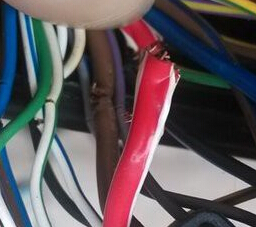

The car harness is the main body of the car circuit. At this stage, the form of the wire harness is generally composed of wires, connectors, harness wrapping materials and body fasteners. Automotive wiring harness to ensure that the transmission of electrical signals, but also to ensure the reliability of the circuit connected to the electrical and electronic components to supply the specified current value to prevent electromagnetic interference to the surrounding circuit, and to exclude electrical short circuit.

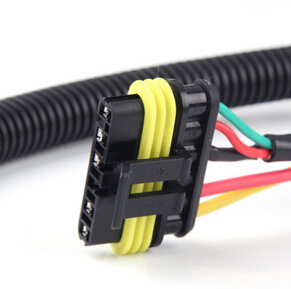

The vehicle harness connector is an important connecting element for each connection point of the automobile circuit. Its quality is good or bad, a direct impact on the power or signal transmission. Therefore, the choice of the appropriate connector, to ensure the reliability of the car line is of great significance. At present, the wiring harness development process used by the connector, the vast majority of brand switches are selected mature products, which shorten the development cycle, but also reduce the development risk.

First, the principle of selection of connectors

According to the basic performance of the connector, the selection of the connector from the electrical performance, mechanical properties of two aspects to consider.

1. Electrical performance

The connector is the basic element that connects the electrical circuit of the car. Therefore, the electrical parameters of the connector itself are the first consideration when selecting the connector. Electrical performance and sub-rated voltage, contact resistance, insulation performance of three aspects.

2, rated voltage

Rated voltage, also known as the operating voltage, the rated voltage of the connector. The rated voltage provided by the connector manufacturer is the maximum operating voltage of the connector. For low-voltage connectors, the manufacturer's voltage is typically 50 V. In general, the connector can work properly below the rated voltage.

The influencing factors are: the insulator material used for the connector, the spacing between the conductive terminals, and so on.

3, contact resistance

The contact resistance directly affects the signal transmission and electrical connection of the electrical equipment of the automobile, which affects the stability and reliability of the electrical equipment.

The influencing factors are: terminal material, terminal contact interface geometry, terminal positive force, terminal contact interface surface state.

4, insulation performance

The insulation performance of the connector is also an important electrical performance, reflecting the insulation properties of the insulation resistance and insulation dielectric strength is to ensure reliable operation of the connector the most basic electrical parameters.

Influencing factors are: materials, temperature, humidity, chemical test solution, dust and so on

Second, mechanical properties

The electrical connectors of the automotive connector are held and positioned by means of a plastic housing sheath; sealed and waterproofed by seals; assembly of terminals and sheaths through terminal and sheath fit, assembled in place Elastic Restore the realization of the jacket on the positioning of the terminal; part of the connector there are shield protection.

Therefore, according to the use of the connector environment, power conditions, environmental and other factors to consider, select the appropriate structure and materials.

➤ Selection in general

1, the plug to choose to ensure good contact with the electrical parts, so that the contact resistance is reduced to the lowest, improve reliability;

2, the preferred choice of double spring-type compression structure of the connector;

3, the preferred use of self-locking connector;

4, the preferred use of the same manufacturers matching the connector;

5, according to the cross-sectional area of the wire through the size of the current reasonable choice of connectors.

6, for the requirements of high performance airbags, ABS, ECU and other terminal fittings, should be preferred to use gold to ensure safety and reliability.

7, the engine compartment docking jacket, due to the cabin temperature, humidity and there is a lot of corrosive gases and liquids, the choice of waterproof connector;

8, the chassis area selection waterproof connector, the cab can choose ordinary connector;

9, the choice of waterproof connector, the plug should be added waterproof plug, the gap should be added waterproof plug;

10, if the same connector in a variety of different diameter, should use a hybrid connector, the assembly is easy to fix;

11, based on the overall appearance of the car coordination, the engine compartment should be preferred black or dark jacket;

12, the same branch point as far as possible the use of different connectors, if you must use the same model, the available color distinction;

13, with a harness in the same kind of sheath, available color distinction.

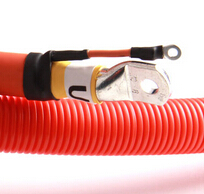

14, the battery connector (battery clip) for the internal cone, taper 1: 9; battery clip material for tinned copper, galvanized copper or lead antimony alloy.

A series of 10A, about 30A;

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite