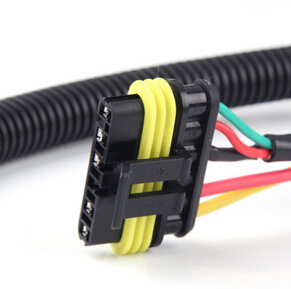

The connector is the core component of the wiring harness. The performance of the connector directly determines the overall performance of the wiring harness. It also plays a decisive role in the stability and safety of the entire vehicle.

First, the choice of connector design principles

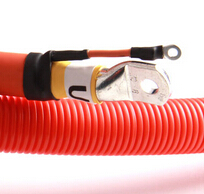

Selection of connectors to ensure good contact with electrical devices, contact resistance to a minimum, to improve reliability, preferably with double spring-loaded compression structure of the connector. According to the cross-sectional area of the wire and the size of the current through the reasonable choice of connectors. Engine compartment butt sheath, due to cabin temperature, humidity is too large and there is a lot of corrosive gases and liquids, so be sure to choose waterproof jacket. In the same harness in the same kind of jacket, the color must be different. Based on the overall coordination of the car's exterior, a black or dark jacket should be preferred in the engine compartment. In order to reduce the type and quantity of the harnesses for docking, it is preferable to use hybrid parts to make the assembly easy and convenient. For the high performance of airbags, ABS, ECU and other terminal connectors, should be preferred to use gold-plated parts to ensure safety and reliability.

Second, the connector material (material) performance analysis

1. Sheath material (plastic parts)

Commonly used materials are mainly PA6, PA66, ABS, PBT, pp and so on. When the design of the plug-in can choose different materials according to different needs, but also according to the actual situation in the plastic add flame retardant or reinforced materials, in order to achieve the purpose of enhancing or flame retardant, such as adding glass fiber reinforced.

2. Terminal material (copper)

The copper used for the connectors is mainly brass and bronze (the hardness of brass is slightly lower than the hardness of bronze), among which the proportion of brass occupies a larger proportion. In addition, according to different needs, choose a different coating.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite