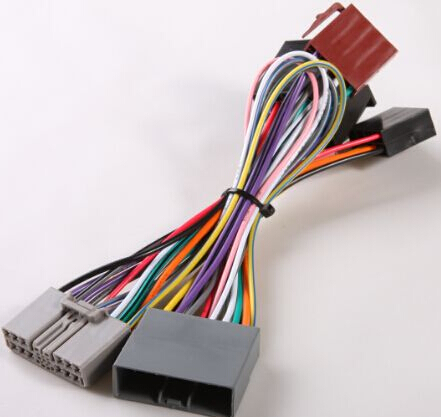

In the era of science and technology industry, the production process of electric vehicles harness more and more sophisticated, we work together to understand the wiring harness production process it!

The first station in harness production is the open line process. The accuracy of the open-line process is directly related to the entire production schedule. In the event of an error, especially if the open-wire size is too short, the rework of all the stations will be caused, which may affect the production efficiency time-consumingly and laboriously.

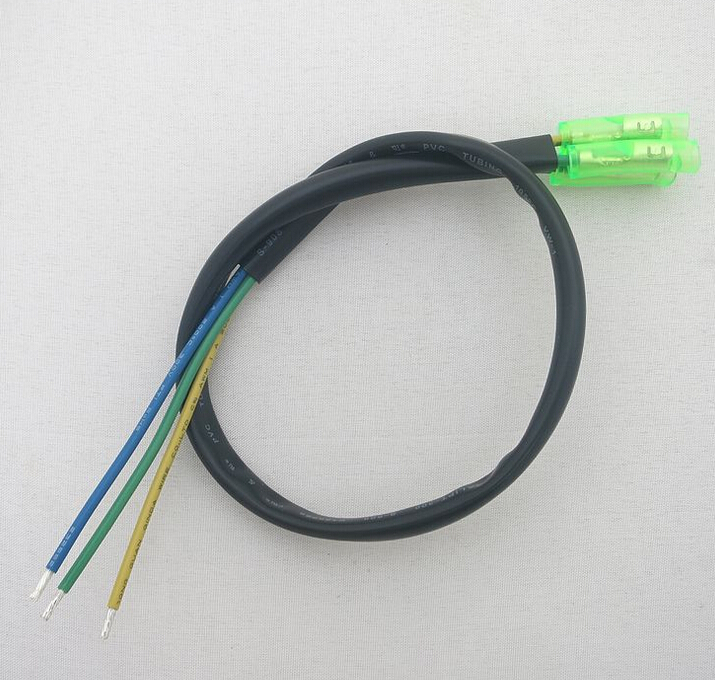

The second station after opening the line is the crimping process. The crimping parameters are determined according to the terminal type required by the drawing, and the crimping operation instruction is made. For the special requirements, the operator should be noted and trained on the process document.

Then is the pre-installed technology, we must first prepare the pre-installed process operating instructions, in order to improve the assembly efficiency, complex wiring harness should be installed pre-installed station. If the pre-installed part of the assembly is too small or assembly of the wire path is unreasonable will increase the total assembly staff workload.

The final step is the assembly process. According to the assembly board designed by the product development department, design the tooling equipment, material box size and size and affix the numbers of all assembly sheaths and accessories to the material box to improve the assembly efficiency.

Electric vehicle wiring harness in the car electronic technology and quality, has gradually become an important indicator to evaluate the performance of electric vehicles. Electric car manufacturers for the choice of wiring harness is also very particular attention, it must be aware of the electric car wiring harness technology and production.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite