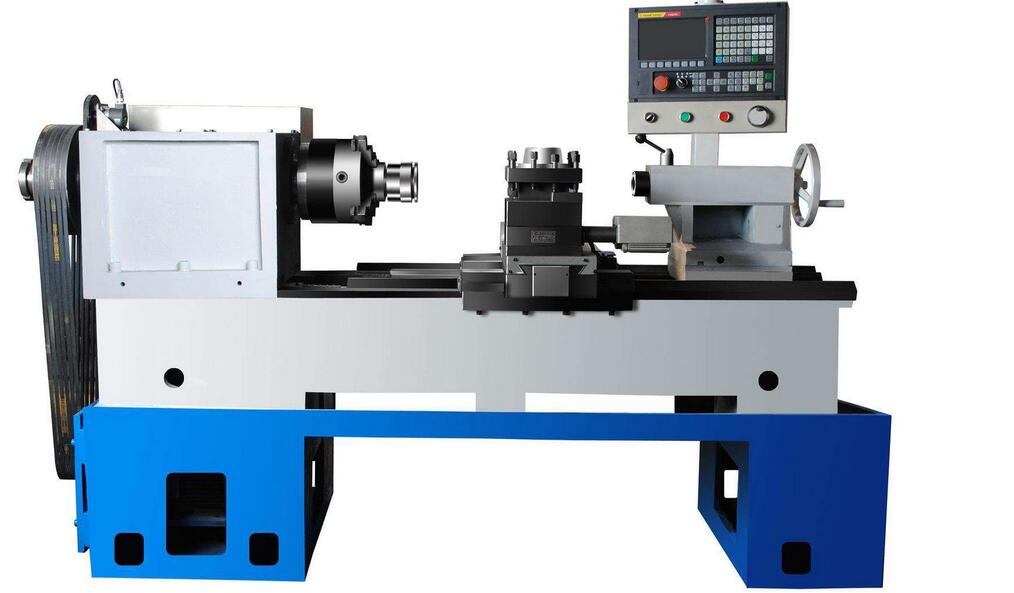

CNC machine tools in the machining accuracy, degree of automation, production efficiency, labor intensity and other aspects of ordinary machine can not match the advantages, but the purchase of new CNC machine tools, especially large CNC machine tools, high cost, often make many users hopeless, In particular, developing countries such as ours have limited funds and, as a result, most machinery factories want to buy and can not afford CNC machine tools. How to get CNC machine tools with less investment is a question worth exploring. Can not buy a new CNC machine tool while the original machine upgrade, so that it becomes a CNC machine? The answer is yes.

In recent years, China's machine tool industry, rapid economic growth, the production of CNC machine tools rate has improved. However, there are more than 4 million kinds of common machine tools in our country. Among them, one-fourth of the machine tools have a service life of more than 30 years. These machines have no value in reconstruction and need to be eliminated. The remaining about 70% of the machine tools can be digitally controlled . The rebuilding and updating of many ordinary machine tools can create hundreds of billions of new market needs and play a certain role in maintaining economic growth.

On the other hand, CNC machine transformation not only saves costs, but also improve processing efficiency. General large-scale machine transformation, only the new machine purchase costs 1/3. While saving costs, you can also save due to all the updates caused by the corresponding energy consumption and pollution emissions. The transformation of ordinary CNC machine tools, machine efficiency will be significantly improved, a substantial increase in machining accuracy. The original one machine needs a person to control, after the transformation of a worker can manipulate two machines at the same time, the rate of rejection caused by human error is also significantly reduced. At the same time, remanufacturing reduces the labor intensity of workers, saves labor, shortens the trial period and production cycle of new products, and brings enormous economic benefits to the enterprise.

In addition, the machine tool by the NC transformation, the safety performance has been significantly improved. At present, the number of ordinary machine tools used in our country is huge, and the security issue has become a major obstacle to its development. CNC machine tools to complete the transformation of the NC, the machine can greatly improve the processing efficiency and automation, the degree of intelligence to reduce the risk of exposure to the operator the possibility of reducing the operator's error rate and reduce errors arising from the accident, the accident rate significantly Lowering will bring huge safety benefits.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite