During the process of using three-phase asynchronous motor, due to motor selection reasons and improper storage and maintenance, environment and other factors cause the moisture to enter the motor to form condensation or direct water inlet of the motor, causing the motor insulation resistance to drop, affecting the normal use of the motor and running safety . Followed by the main site for damp squirrel cage motor in different conditions, the method of drying analysis introduced.

1, small capacity three-phase asynchronous motor damp handling methods:

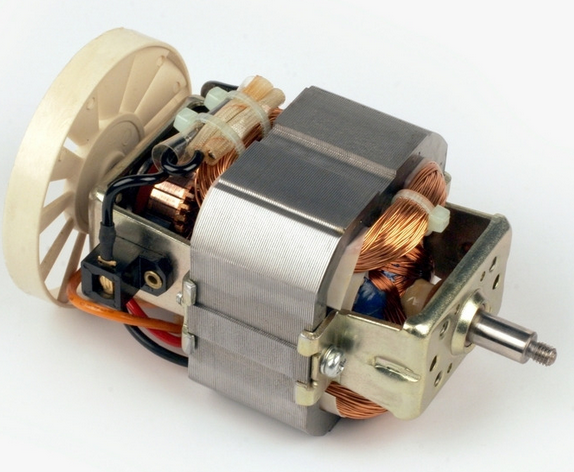

Drying method: small capacity asynchronous motor disassembly, disassembly is more convenient, can be carried out on-site drying or disassembly to the maintenance room for processing, the following two methods can generally be used to dry the motor.General small low-voltage asynchronous motor suitable for external heating motor drying method, the operation is relatively simple; the principle is dry when the use of external heat radiation, convection, conduction to dry the motor; generally divided into two methods:

(1) the use of light bulbs (or infrared light bulbs), oven drying, the use of hot air dryer for drying;

(2) The use of light bulbs or tungsten lamp drying should not be too close to the coil, to prevent baking coil, you must use safety protection lamps, the use of the oven temperature can not exceed 100 ℃.

2, large and medium-sized three-phase asynchronous motor damp handling methods:

Drying methods are the following:First: current drying method:

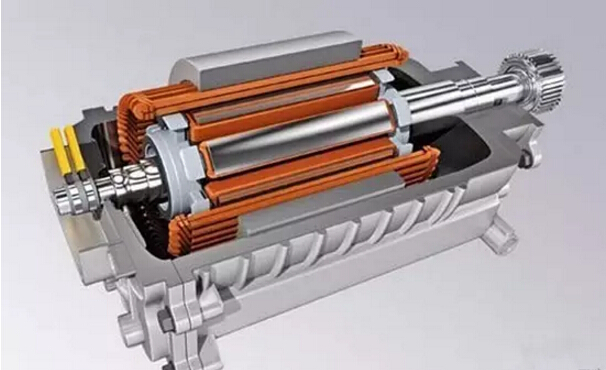

Current drying method is the basic principle of the motor stator winding access low-voltage current, the rotor locked rotor, the use of motor losses generated by the temperature to dry the motor, the drying of the motor while the stator heat, drying faster, generally used for capacity than Large high and low voltage motor;

Note: Calculate the locked rotor current per phase distribution of the maximum current, should not exceed the original rated current of 50% to 60%, you can choose the voltage level to dry.

Second: Motor iron loss drying methodThe basic principle of the iron loss drying method is that the excitation coil is wound on the iron core of the stator winding of the motor and the alternating current is applied to make the stator iron core produce magnetic flux and use the temperature rise caused by the eddy current loss of the iron core to dry the motor.

3, three-phase motor damp matters needing attention:

① The rotor out of the motor, heating and drying should be carried out in clean air, clean the various parts of the motor before drying.

②When the motor is dry, the winding temperature of the motor must be lower than the temperature required by its insulation level (for the sake of safety, the temperature is preferably lower than its specified temperature 10 ℃), the winding temperature is generally controlled at 70 ℃ ~ 80 ℃ optimal.

③ windings over-humid motor, you can not use the DC current drying method, direct current electrolysis.

④ current, iron loss method is dry, the motor shell must have a good grounding wire to prevent electric shock. When using a light bulb or a halogen lamp for baking, care should be taken to prevent electric shock.

⑤ closed motor, do not pull out the rotor is dry, the motor junction box or check hole to open a certain gap, a small low-voltage motor can also open the motor cover a gap, in order to facilitate the motor moisture distribution.

⑥ in the drying process, the timing of the winding temperature measurement and insulation resistance, and make a record. Drying the initial stage of every 15 ~ 30 min record 1 ~ 2 h after the record must be timed motor temperature to prevent motor overheating caused damage.

In fact, there are many specific ways to dry the motor after it gets wet. At the production site, the proper drying method should be used to dry the motor according to the specific conditions. However, no matter what method of drying the motor, we must pay attention to the motor temperature can not exceed the allowable value, New damage to the motor insulation, pay attention to the safety of equipment and personal safety during drying; the production site often requires the motor to be put into operation in time and safe operation, the southern environment rainy and humid, in order to ensure that the motor is not affected by dampness, Put into operation or safe operation, should develop specific measures to prevent moisture motor should also pay attention to humid environment motor selection.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite