For five consecutive years, China has become the largest consumer of industrial robots. Data shows that in 2017, 136,000 new industrial robots were added to the domestic market, an increase of 60% year-on-year. At the same time, in the battle for market competition, domestically-developed industrial robots of their own brands still have a long-term disadvantage.

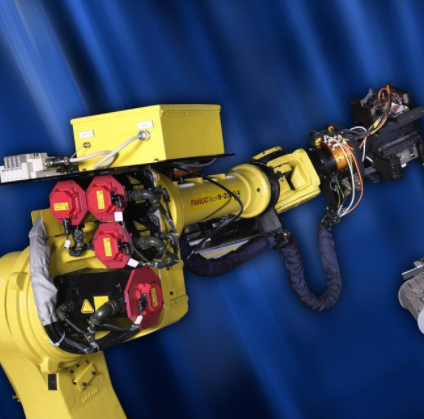

According to analysis by industry experts, foreign companies occupy a leading position in the field of industrial robots by virtue of their first-mover advantage and technological accumulation, and ABB and other four families occupy about half of the market share of industrial robots. In contrast, China’s robotics companies are facing shortages of professionals, scarcity of core components, and inadequate market recognition. Against this backdrop, there are views that the emergence of collaborative robots has created new opportunities for domestic robots that are struggling to catch up.

Yi Jianqiang, a member of the National Committee of the Chinese People's Political Consultative Conference and a researcher at the Institute of Automation of the Chinese Academy of Sciences, told a reporter from Science and Technology Daily that collaborative robots are a research direction that has emerged in recent years. "It emphasizes that robots cooperate with humans, or robots and robots cooperate to accomplish specified tasks together."

The “Blue Book for Cooperative Robot Industry Development 2017” released by a research institute shows that from 2014 to 2016, the compound annual growth rate of global collaborative robot sales and market scale was 74.71% and 71.23%, respectively.

According to statistics from China Robotics Industry Alliance, from 2013 to 2016, from the point of view of the number of sales units, the proportion of domestic industrial robots has been around 25% to 32%, and the share increase is not obvious. In the first half of 2017, sales volume of domestic industrial robots increased by approximately 20% year-on-year, far below the industry growth rate. "Collaborative robots are an effective means for SMEs and companies with flexible production requirements to realize smart manufacturing, and they are also opportunities for domestic robotics companies to realize cornering overtaking in the market." Zexu Wang, CEO of Zeta Technology, who is committed to the development of modular collaborative robots, believes.

"The cooperation robot based on the joint module can be customized in technology, the price is between 100,000 and 300,000 yuan, and the use cost of the later period can be greatly reduced through joint multiplexing. This mode of production can be customized in small batches. SMEs that are mainly based and unable to invest too much capital in large-scale transformation of the production line are more attractive, said Wang Xiezhe.

At the same time, although the core technology of China's robotics industry needs to be strengthened, the complete industrial system in China makes the upstream and downstream industrial chains of the robot relatively perfect, which is also conducive to the development of collaborative robots.

"Taking the harmonic components of the core components of robots as an example, there are only a handful of manufacturers able to ship products around the world. The quality of Japanese products is the best, but the price and delivery period are very harsh for domestic companies. Domestic Harmonic Deceleration The device has made remarkable progress and can meet the requirements of collaborative robots. For cooperative robot customers who are more sensitive to price and flexibility, the advantage of adopting domestic suppliers is significant.” Wang Xiaozhe said, “We especially hope that all parties in the SME and robot industry chain We can focus on collaborative robots and reconfigurable robots, and work together to contribute to China's smart manufacturing and industrial upgrading.”

Yi Jianqiang pointed out that despite the development of robots in recent years, the awareness of the environment based on artificial intelligence has greatly improved, but some aspects are still insufficient, and there is a gap in judging each other’s intentions. Therefore, it is necessary to achieve a complex environment. Robot collaboration also requires the joint efforts of the scientific and technological community and the business community.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite