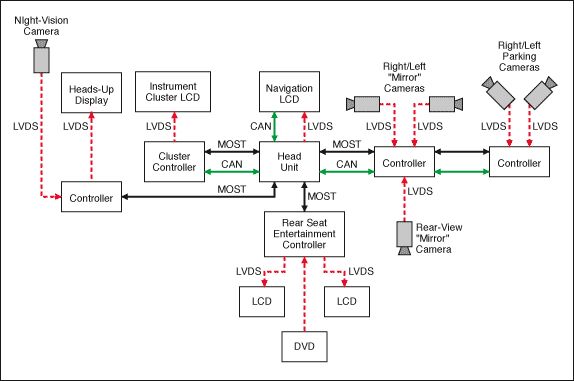

With the increase in the popularity of automobiles, users are increasingly demanding automobiles. In order to meet the market demand, researchers constantly transform and optimize the car to make it more intelligent, which will inevitably use more harnesses to control the car. This not only improves the intelligence of the car, but also adds many new problems. For example, the complexity of the circuit also increases. This reduces the reliability of the car to some extent, increases the difficulty of maintenance, and aggravates the car. Quality, occupy a lot of space. After research and development, the researchers changed the line-to-line control in the past to the first-line and multi-use, so as to achieve maximum space savings and improve the overall efficiency of the system, to make full use of limited resources. It is in this way that the number of harnesses is simplified, the space occupied is reduced, the utilization rate is increased, the reliability of the automobile is increased, the intelligence level of the vehicle is increased, and the development of intelligent automobiles is accelerated. The appearance of this approach also puts higher requirements on the wiring harness, prompting changes in the manufacture of the harness and the manufacture of the connector. How can that be done to meet this requirement?

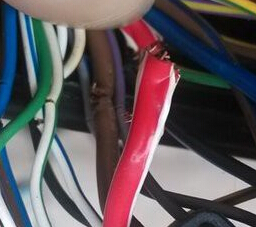

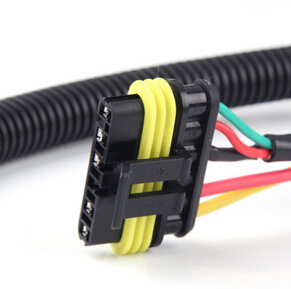

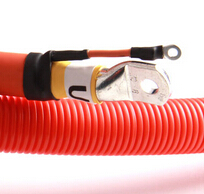

First, the manufacture of wire harnesses should be strictly controlled by the choice of raw materials. In the corresponding industry or national standards have clear requirements on performance requirements, but most of the performance indicators on the performance and requirements of the beam is different, researchers should analyze and study the different materials of the wire, through comparison of the advantages and disadvantages of the wire, and then According to the requirements of automotive performance, choose the appropriate wire.

Second, when the performance and quality of raw materials and parts meet the requirements, the process quality and physical quality control of each process must be strictly controlled in the manufacturing process of the wire harness.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite