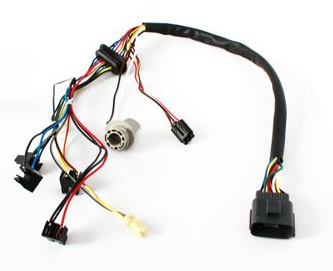

The choice of wire type for automotive wiring harness design focuses on the environment and function of the wiring harness. For example, the ambient temperature around the engine is high, and there are many corrosive gases and liquids. Therefore, it is necessary to use high temperature, oil resistant, vibration and friction resistant wires; the wires on the trunk lid should maintain its elasticity at low temperatures, so use cold elastic wires to ensure normal operation; the wires on the automatic transmission must be resistant. High temperature and hydraulic oil resistance have good temperature stability; weak signal sensors use shielded wires, such as knock sensor and crank position sensor, ABS wheel speed sensor, etc.; the inner wire has high bending resistance requirements.

Commonly used wires for automotive wiring harnesses usually use stranded copper wires, and the insulation is PVC insulation. Wire harness wire should have the characteristics of temperature resistance, oil resistance, wear resistance, water resistance, corrosion resistance, oxidation resistance and flame retardancy. The types of wires commonly used in automotive wiring harnesses include Japanese standard (AVSS, etc.), national standard (QVR), German standard (FLRY), and American standard.

AVSS (AVS) wire is characterized by thin skin insulation and good flexibility; QVR is characterized by thick insulation, soft and good ductility; German standard wire insulation is thinner and flexible; American standard wire insulation is generally Thermoplastic or thermoset elastomers, as well as processed by irradiation. The appropriate type of wire can be selected according to the needs of the user and different working environments.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite