Linear motor "zero transmission" is superior in machine tool feed system

(1) High speed responsiveness

In general, mechanical transmissions are orders of magnitude larger than the dynamic response time of electrical components. Because some mechanical transmission parts such as lead screws with large response time constant are eliminated in the system, the dynamic response performance of the whole closed-loop control system is greatly improved, and the reaction is extremely sensitive and quick.

(2) High precision

Since the mechanical transmission mechanism such as the lead screw is eliminated, the tracking error caused by the delay of the transmission system during the interpolation is reduced. Through the linear position detection feedback control, the positioning accuracy of the machine tool can be greatly improved.

(3) High transmission rigidity and stable thrust

"Direct drive" increases its transmission stiffness. At the same time, the layout of the linear motor can be arranged according to the shape and surface structure of the machine guide rail and the force applied during the movement of the table. It is usually designed to be evenly symmetrical, making its motion thrust smooth.

(4) Fast speed, short acceleration and deceleration process

Linear motors were first used mainly for maglev trains (up to 500km/h) and are now used in machine feed drives to meet the maximum feed rates for ultra-high-speed cutting (up to 60-100m/min or higher). It is ok. Due to the high-speed responsiveness of the “zero transmission”, the acceleration and deceleration process is greatly shortened, so that the high speed can be achieved instantaneously at the time of starting, and the instantaneous stop can be instantaneously performed at high speed. The acceleration can generally reach 2 to 10 g (g = 9.8 m / s 2).

(5) Unlimited length of stroke

By linearly stepping the stator of the motor on the guide rail, the stroke length of the moving member can be extended indefinitely.

(6) Low noise during operation

Since the mechanical friction of the components such as the drive screw is eliminated, the guide rail pair can adopt the rolling guide or the magnetic pad suspension guide (no mechanical contact), so that the motion noise is greatly reduced.

(7) High efficiency

Since there is no intermediate transmission link, the energy loss during mechanical friction is eliminated.

(8) Adopt full closed loop control system

Since the mover of the linear motor has been combined with the work table of the machine tool, unlike the ball screw feed unit, the linear motor feed unit can only use the full closed loop control system.

Related articles

-

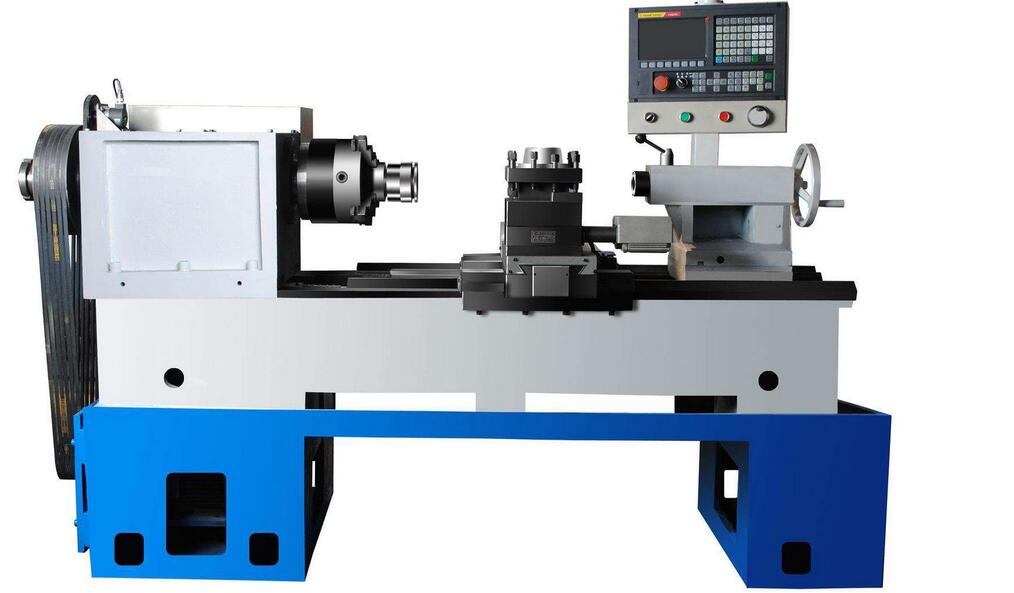

Configuration and Function Selection of Machine Tool Numerical Control System

CNC system configuration and function selection system is an important part of CNC machine tools, configuration, what kind of CNC system and choose which CNC functions are machine manufacturers and en

-

German machine tool orders exceeded expectations rose 23%

According to the German Machine Tool Manufacturers Association recently released data show that the first quarter of 2017, the German machine tool industry orders increased by 6% over the same period

-

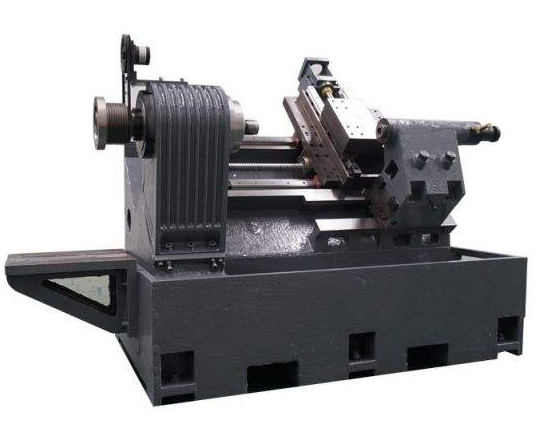

Cause Analysis on Instability of Machining Workpiece in NC Machine Tool

1, the workpiece scale is accurate, poor surface finishCause: cutter tip damage, not sharp; machine resonance, placement is not smooth; machine has a creeping phenomenon; processing technology is not

-

How much impact does the electric car have on the machine tool market?

During the 2017 period, the Oxford Economic Forecasting Center organized the Association to convene a Market Forecast Coordination Committee. One of the topics discussed was the impact of the developm

-

Causes of Abnormal Machining Accuracy of NC Machine

First, the formation of abnormal processing accuracy of the reasonsThe formation of processing accuracy of the causes of abnormal problems hidden strong, relatively difficult to diagnose, summed up th

-

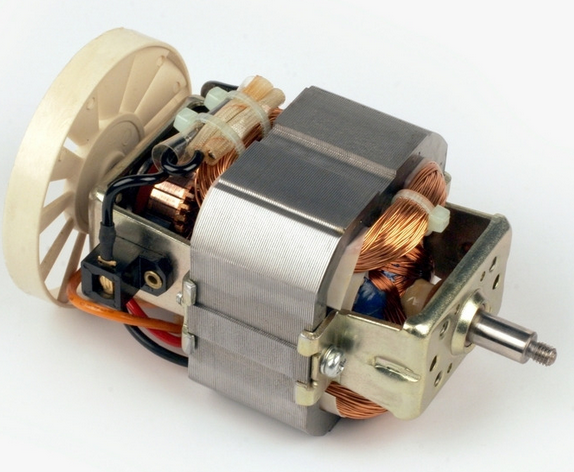

What is the linear motor thrust detection? How to operate?

The amount of linear motor output is mainly thrust, due to the linear motor theory, design, manufacture and load and interference and many other reasons, will cause the linear motor thrust fluctuation

-

Analysis of machining error of CNC machine tools and its causes

In order to improve the machining accuracy of CNC machine tools, technicians must conduct a detailed analysis of the errors generated in the NC machining process to find out the causes of machining er

-

American Machine Tool Management Behind 30 years in East Asia

Is it really because of the industrial transfer of the United States from the so-called sunset industry to the sunrise industry that the world's major economies trade surplus with the United States? In actual fact, one of the most important reasons for the industrial transfer and the trade deficit in the United States is that the United States has gradually lagged behind the world in management, especially in the past three decades. The above is the status of the U.S. auto industry. As for the U.S. shipbuilding industry, we know that at the beginning of the last century the United States specially formulated the Jones Act to protect the U.S. shipbuilding industry

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite