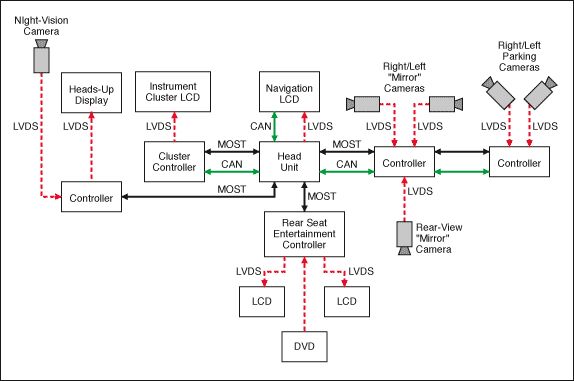

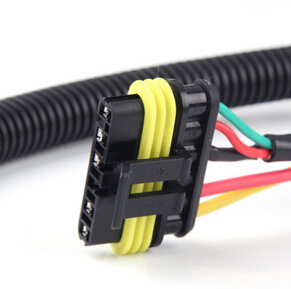

The wire harness connector is used to connect the connection points of automobile circuits. It is an important part on the car. Its quality directly affects the power or signal transmission effect. The cost ratio of the connector in the car is small, but if there is a quality problem in the use of the car, it often has serious consequences, and the maintenance cost increases significantly. Therefore, the quality of the connector is increasingly being obtained by car manufacturers and Attention of component suppliers.

Terminal withdrawal is a more common form of failure for harness connectors. Terminal withdrawal refers to the fact that after the connector is assembled, the terminal is abnormally separated from the sheath, so that the function of the connector is lost. The reasons for the formation of this type of failure generally include three aspects: ① the retaining force of the terminal in the sheath is unqualified; ② interference in the insertion; ③ product application problems. This article analyzes the terminal withdrawal of the connector and proposes solutions based on these three reasons.

1 The holding force of the terminal in the sheath is unqualified

The holding force of the terminal in the sheath refers to the force required to separate the terminal from the sheath in the axial direction.

In order to avoid the phenomenon of terminal withdrawal, the performance test standard of the connector strictly stipulates the holding force of the terminal in the sheath: ① the holding force of the connector with a size not greater than 2.8 is greater than 40N; The holding force of the connector is greater than 60N.

In practice, many terminal withdrawals occur because the holding force does not meet the requirements. In general, the reasons for the failure of the terminal's retaining force in the sheath are: structural design issues and material selection issues.

1.1 Structural design issues

The structural design problem mainly refers to the design of the connecting structure of the terminal and the sheath. This hook structure is generally an elastic structure, which is divided into an elastic structure on the sheath and an elastic structure on the terminal.

1.1.1 Elastic structure on the sheath

The sheath adopts an elastic structure. The elastic structure required for the assembly of the terminal and the sheath is designed on the sheath. During the assembly of the terminal and the sheath, a force is applied through the sheath spring (the elastic structure designed on the sheath). Deformation to achieve the assembly of the terminal and the sheath. After the terminal and the sheath are assembled in place, the sheath tongue is restored to its original state due to the release of force. The cooperation of the sheath spring tongue and the hanging structure designed on the terminal ensures the effective positioning of the sheath on the terminal. The shear strength of the sheath tongue determines the retention force of the terminal in the sheath. The shear stress calculation formula is as follows:

In the formula: τ ———— shear stress on the material; F ———— force in the shear direction of the material; A ———— shear area; [τ] —— allowable yield shear stress of the material.

It can be known from formula (1) that the maximum force in the shearing direction of the material is proportional to the shear area of the material and proportional to the allowable shear stress of the material. In the design of the sheath tongue, after the material is selected, the allowable yield shear stress of the material is fixed. To ensure that the product meets the requirements of the terminal's holding force in the sheath (stress in the shear direction), the sheath must be guaranteed. The shear area of the spring tongue meets the required value.

In practice, because the design clearance between the terminal and the sheath is taken into account, the shear area should be calculated according to the extreme severe conditions. The design clearance between the terminal and the sheath should be able to ensure that the shear area calculated under extreme conditions can withstand the yield shear stress greater than the required terminal retention force in the sheath.

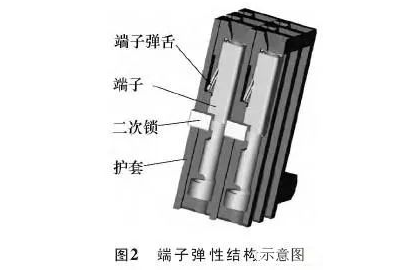

1.1.2 Flexible structure on terminals

The use of an elastic structure on the terminal refers to designing the elastic structure required for the terminal and sheath assembly on the terminal. During the terminal and sheath assembly process, the terminal spring tongue (the elastic structure designed on the terminal) is deformed by force to achieve Terminal and sheath assembly. After the terminal and the sheath are assembled in place, the terminal spring tongue is restored to its original state due to the release of force. The cooperation of the terminal spring tongue and the hanging structure designed on the sheath guarantees the effective positioning of the terminal by the sheath.

The yield strength of the terminal spring tongue determines the retention force of the terminal in the sheath. According to formula (1), when designing the terminal spring tongue, when the material is selected, the allowable shear stress of the material is fixed. It is necessary to ensure that the product meets the requirements of the terminal's holding force in the sheath (stress in the shear direction). To ensure that the shear area of the terminal spring tongue meets the required value.

In practice, because the design clearance between the terminal and the sheath is taken into account, in addition to considering the shear area (material thickness and tongue width) of the terminal spring tongue, it should be ensured that the terminal spring tongue is hanging on the sheath in the worst case. The platform structure has a complete fit.

1.2 Material selection issues

1.2.1 Sheath material selection

Common materials for connector jackets are: polyamide (commonly known as nylon), polybutylene terephthalate (PBT), ABS, etc.

For the sheath tongue structure, the toughness of the material is generally considered, and the size of the tongue structure is designed according to the allowable yield shear stress of the material that meets the toughness requirements.

It should be emphasized that the allowable yield shear stress of the material should be calculated according to the allowable values of the material after the test of high temperature aging, temperature-humidity cycle, and chemical liquid corrosion that the connector may have. If the design of the bullet tongue structure according to the allowable yield stress value after the test fails to meet the requirements, consideration should be given to replacing the material or using a secondary lock structure (Figure 2) to solve it.

When the initial holding force of the connector is normal, and the needle is retracted after the test fails, it is generally caused by the design of the spring tongue structure according to the initial allowable yield shear stress of the material used.

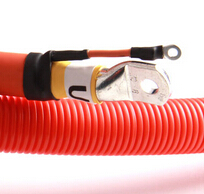

1.2.2 Terminal material selection

Common materials for connector terminals are: copper, brass, bronze. According to their hardness, they can be divided into three states: soft, semi-rigid and hard.

Of these three materials, copper is less commonly used, and is generally used for grounded hole or fork joints. Brass and bronze are more commonly used. Brass has better conductivity than bronze, and bronze has better hardness and elasticity than brass. When using the terminal spring tongue structure, bronze should generally be used. The use of brass materials often results in insufficient retention.

2 terminal mating interference

Terminal mating interference refers to the form of failure of the connector when the male and female ends of the connector are mated, because the male terminal is inserted into the female terminal inactive area, causing the connector to lose its functions such as terminal withdrawal. Generally speaking, the reasons for the interference of terminal insertion are: ① structural design problems; ② terminal insertion and extraction force problems.

2.1 Structural design issues

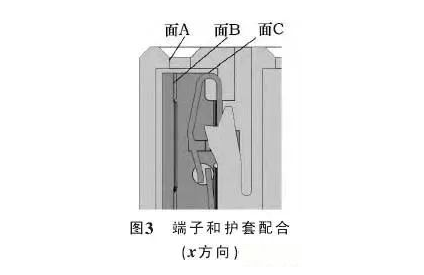

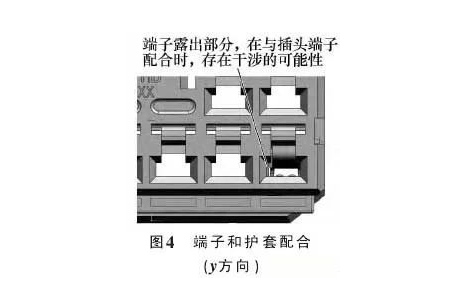

The structural design problems of the connector that involve the interference of the terminal are mainly: the design of the center distance of the connector (including the wrong size or excessive tolerance), the design of the clearance between the terminal and the sheath (including the excessive or excessive Small) etc.

When there is a problem with the structural design, there will be misalignment of the male and female terminals during the mating process of the connector. When this misalignment occurs in the x direction (Figure 3), the male terminal will be on top of face B or face C. When the degree is light, it will cause the plug connector to pull out too much, and when the degree is serious, it will cause the terminal to withdraw. When this misalignment occurs in the y direction (Figure 4), the exposed part of the female terminal will appear, and the male terminal will easily push against the exposed part of the female terminal. When the degree is lighter, it will cause the plug connector to have a larger insertion force. If it is serious, it will cause the terminal to withdraw.

For example, in the assembly process of the fuse box and the harness of the engine compartment of an automobile factory assembly assembly, there have been frequent withdrawals of the connector end of the harness end and the insertion force is large, and the incidence of withdrawal is 15%, and the insertion force is large For all. After analysis of the problem pieces, it was found that due to the design of the center distance of the corresponding fuse box structure mating with the harness end, the male and female terminals were misaligned during the mating process, resulting in the assembly process of the harness end connector and the fuse box The middle insertion force is large and the terminal end of the harness end connector is withdrawn. This problem was solved by improving the design of the corresponding structure of the fuse box.

2.2 Terminal insertion force

Due to the requirements of assembly performance, the insertion and extraction force of the connector terminal should be as small as possible, and an excessively small insertion and withdrawal force will increase the contact resistance of the connector and reduce the conductivity. Therefore, a suitable terminal insertion force is to meet the requirements of the connector assembly performance under the premise of ensuring the electrical performance of the connector. In order to improve the terminal's electrical conductivity, the insertion and extraction force of the terminal is often increased in practice. Generally, this will cause assembly difficulties. When the terminal insertion and removal force is greater than the holding force of the terminal in the sheath, it may cause the terminal to withdraw during the mating process of the connector.

03 Product Application Problems

Product application problems involving the withdrawal of connector terminals mainly refer to the problems that may cause the terminals to withdraw during the wire harness production process. Generally includes terminal crimping problems and terminal assembly problems.

"Banana" terminals are a common problem in terminal crimping. Refers to the excessive bending of the terminal caused by improper crimping, which makes the center line of the terminal's joint area and the crimp area not parallel, as shown in Figure 5.

When the degree of excessive bending is light, the insertion and extraction force of the connector is increased, which affects the assembly performance; when the degree of serious bending is caused, the male terminal cannot be inserted into the effective insertion area of the female terminal during the mating process of the connector, thereby causing the terminal to withdraw. .

For example, during the mating assembly of rear lights and wiring harnesses in the assembly shop of an automobile factory, there have been frequent withdrawals of the connector terminals of the wiring harness end, with a rate of 20%. After analyzing the problem, it was found that Some terminals are excessively bent (banana terminals), causing the harness end connector terminal to withdraw during the assembly process of the harness end connector and the rear tail light. After crimping the terminals, this problem was resolved.

4 Conclusion

There are three reasons for the withdrawal of the connector terminal:

① The retention force of the terminal in the sheath is unqualified—generally caused by design reasons, manufacturing reasons, or reasons for using materials;

② Interfering interference --- generally caused by design or manufacturing reasons;

③ Product application problems-mainly caused by inappropriate use methods in the product use process.

In actual use, if the terminal withdraws, the cause of the problem should be analyzed first, and the problem should be solved in a targeted manner.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite