With the rapid development of the economy in the past two decades, China's per capita electricity consumption has doubled, but the electrical fires also increased dramatically, to the national economy and people's lives and property caused great losses. According to the Ministry of Public Security Fire Department, "China Fire Yearbook" (2014), 2013, the national total of 388,000 fire statistics, death 2113 people, injured 1637 people; but in 2013 due to electrical fire caused a total of 11.6 million, 745 deaths , Injured 538 people, respectively, the total number of 29.7%, 35.3% and 32.9%. So the prevention of electrical fires is very important.

Electrical fire analysis

⊙ electrical fire fire source

From the mechanism of electrical fire to see the main part of the failure of local long-term fever, resulting in further decline in insulation, and ultimately lead to short circuit lines, resulting in fire; the other is the fault generated by the arc or spark instantaneous release of heat caused by short circuit, resulting in fire.

EDM and arc are mainly produced in the gas or liquid insulating material. After the insulation is damaged, an arc is generated between the cracks or the crack, and the voltage between the two conductors is broken to produce an arc of 30 kV / cm. Arc will produce a high temperature, such as 2 ~ 20A of the arc current can produce 2000 ℃ ~ 4000 ℃ local high temperature, 0.5A arc current is enough to cause a fire. EDM can be seen as unstable, very short duration of the arc, the temperature is also high, by the spark, the arc generated by the secondary fire has a greater risk.

Electrical equipment and lines in the run-time will always heat, for the following reasons:

1, the current in the conductor resistance to heat;

2, the heat generated by the core loss;

3, the heat generated by the dielectric loss of insulation.

Under normal circumstances, heat and heat can be balanced at a lower temperature, the temperature does not exceed the long-term allowable operating temperature of electrical equipment, there will be no danger of high temperature, only when the normal operation was destroyed, so that heat surge And the heat is less, then it may appear a sharp rise in temperature, as well as dangerous high temperature, this dangerous high temperature in the right time will cause a fire. Dangerous high temperature caused by the fire more complex way, its effect is mainly softened insulation, decomposition of the material can produce (easy) gas, direct baking substances.

⊙ Analysis of electrical fires

To the commonly used PVC insulated wire cable combustion research as an example

In the case of heat

The insulation was started to soften at 85 ° C at a temperature of 20 ° C per minute at 20 ° C / min. At about 159 ° C, the insulating layer was clearly discolored and a very small amount of gas was precipitated; a small amount of organic gas was measured at about 240 ° C, At this point the insulating material begins to crack; a large amount of gas is produced at about 288ºC; the weight is rapidly reduced at about 328ºC, HCI is released in the gas; HCI, plasticizer and carbonaceous oxide are released at 385ºC; the major decomposition product at about 477ºC is CO And water, the insulation material is completely carbonized, the conditions will have to burn.

In the case of overload

Under the ambient temperature of 23 ° C, use a new 1.0mm2 BV conductor (rated load 15A, limit load of 20A), run at load current of 28.5A, and measure the wire temperature. In the overload of 90% (such as the ultimate load capacity of 20A considered, the actual overload of 42.5%) after a period of time its temperature stability at 96.1 ℃, the wire appears softening, a slight irritating odor, indicating a trace of gas precipitation

In the short circuit state

Using a large current generator, at room temperature, the 1.0mm2 BV wire current suddenly rose to 5 times the rated current (75A), for short-circuit simulation experiments, found that the wire temperature rose sharply, and instantly emit a large number of white smoke, a few minutes after the insulation Layer that is carbonized and stripped along the full range, while high temperature droplet dripping. Such as the use of 2.5mm2 BLV wire with its 5 times the rated current (140A) to do short-circuit experiments and found that the core instantaneous fissure in the weak, droplets can ignite the following shredded chips and other combustibles, the temperature close to 300 º C. The actual operating conditions of the short-circuit current is hundreds of times the rated current, the risk can be imagined.

From the above research data can be seen in the cable before the start of combustion, in addition to the cable temperature rise, but also the release of trace gases, including insulating material cracking of organic matter, HCl, plasticizers, carbon oxides, CO and water vapor.

⊙ fire development process

The development of the fire is divided into four stages: budding (not visible smoke), visible smoke, flame and high heat stage. The figure shows the different stages of development of the fire in a given period of time. Pay attention to the fire in the budding stage of the brewing stage provides more time and opportunity to detect and control the development of fire.

The development of the fire is divided into four stages: budding (not visible smoke), visible smoke, flame and high heat stage. The figure shows the different stages of development of the fire in a given period of time. Pay attention to the fire in the budding stage of the brewing stage provides more time and opportunity to detect and control the development of fire.

Most electrical equipment fires are caused by overheating of the equipment, or due to short circuit or discharge of the cable. Once the fire has transitioned to the stage of the flame, the rate of fire spreads faster, creates significant damage and increases the likelihood of paralysis of the job. If an abnormal condition is detected during the embryonic stage of an electrical fire, the maximum strain time will be achieved.

Second, the electrical fire alarm conventional technology

⊙ point type smoke detector in the electrical room in the application

Point-type smoke detectors are the most common type of detectors in the electrical room. They are usually installed under the ceiling. There are three factors that will affect the detection speed of the smoke detector: the path from which the smoke is transmitted from the fire source to the detector, the degree of smoke dilution during transmission, and the detector sensitivity. We should be aware of the following factors that may have a negative impact on the detector response installed in a power plant environment, causing increased detection and increased likelihood of damage:

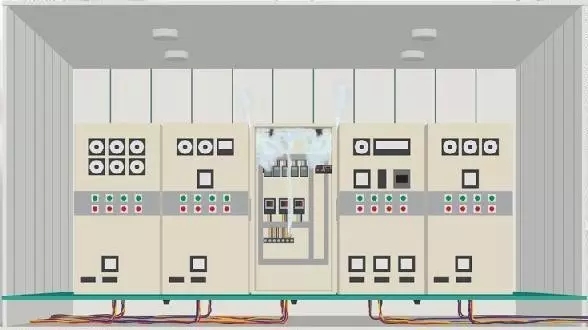

Equipment Seal - These devices are usually enclosed in cabinets due to the high risk of high voltage characteristics of power transmission and power distribution systems. The cabinet may be equipped with an internal cooling fan or air conditioning system to keep the equipment temperature in a safe range. These cabinets have two negative effects on the transmission time of the smoke detectors at the job site:

1, the cabinet will limit the flow of smoke, extend the smoke from the fire source to reach the detector installed on the ceiling of the time.

2, the internal fan and air conditioning system will dilute and cool the smoke, so that the smoke does not have enough thermal buoyancy to rise to the ceiling, to extend the time of the site detector response.

Inside the cabinet when there is smoke, will be covered by the box, even if there is a little smoke leaked to the interior will spread out, generally set in the ceiling smoke sensor is not sensitive.

⊙ suction smoke detectors in the machine room application

Inhalation smoke detectors (commonly known as air sampling detectors, etc.) work is to use the internal detection of the pump inside the pump, connecting the sampling pipeline and capillary hose, extract the air inside the cabinet sample, along the sampling pipeline to send Back to the detection host, in the detection of the host to detect air samples, when the detection of the host to detect abnormal smoke concentration increased when the release of appropriate fire alarm.

Cabinet installation - cabinet installation is the most effective protection of the equipment within the distribution panel, can reduce the pressure and external air pollution on the detection process. This type of detector can react quickly and provide very early warning signals.

In-board installation (from the top of the box)

The sampling pipe of the inspiratory smoke detector is very flexible. The sampling tube can be arranged above the cabinet, and the air inside the cabinet can be extracted by the opening of the hose and the cabinet. Sampling piping can also be configured under the cabinet, using a hose to extend to the top of the cabinet to extract air samples.

In-board installation (from the bottom of the box)

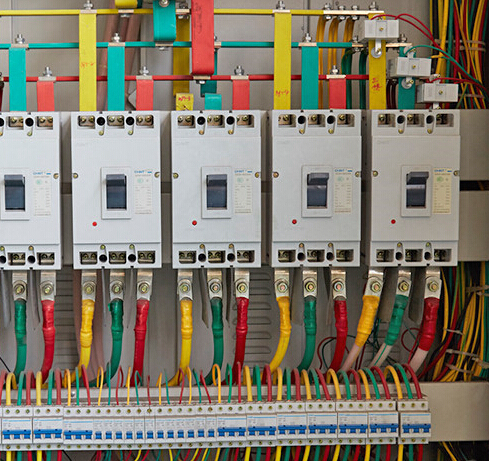

The actual project photo above the box

A typical aspiration smoke detector is installed. All air samples from the disk are passed through a hose to the sampling tube and sent to the detection host for smoke detection. Pipes and hoses are used to extract the air inside the cabinet.

But the need to set the suction smoke detectors need to consider the following:

1, the detector may not be able to determine the specific cabinet where the fire occurred

As the air samples in the cabinet eventually converge into the detector, when the detector detects abnormal smoke increases, and can not know which cabinet is caused by, so you must manually open all the cabinets, find the source of fire. This way to the scene personnel to bring great pressure, and time-consuming.

In addition, the function of each cabinet internal equipment may vary, if only because of similar location and into the air sampling pipeline network system, then, can not follow the different cabinet function or importance to linkage the corresponding contingency measures, so also Weakening the advantages of the very early warning system.

2, the impact of the number of cabinets on the fire sensitivity:

When the number of cabinets protected by a host is increased, the cabinet requires a higher concentration of smoke to cause the detection host to issue an alarm due to the smoke dilution relationship. For example, a detector to protect the 20 power distribution system, then the smoke was diluted 20 times; the same parameters set the detector if only to protect the four cabinets, then the four alarm system sensitivity is theoretically 20 times 5 times, you can advance warning. That is to say, the more the switchboard is protected, the lower the fire sensitivity is.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite