What kind of insulating materials are used for wire harness processing?

PVC (PVC line is 1007 \ 1015 \ 1061,1430,1571) - PVC (PVC) plastic is based on polyvinyl chloride resin-based multi-component mixture, according to the requirements of a variety of wire and cable, In the PVC formula with a plasticizer, stabilizer, fillers, flame retardants, processing aids (lubricants), UV absorbers, colorants and special-purpose additives and other substances, mainly for insulation and sheath (mainly 70,80,90,105 degrees four temperature levels). Basic determination method: burning, yellow flame, black smoke, the bottom of the flame was green, stench.

PE (our commonly used 3266 \ 3385) - Polyethylene has excellent electrical insulation (dielectric constant and dielectric loss tangent tgδ are very small), good chemical stability, low permeability and smaller water absorption Nature, small proportion, non-toxic, and a good plastic, easy processing and molding. Mainly used for communication cable insulation. The basic method of determination: the surface comparison light , burning, the flame on the blue under the blue, dripping, with a slight candle flavor.

PP - polypropylene appearance of white waxy solid, more transparent, non-toxic, water absorption is small, only 0.03-0.04%, combustible. The proportion of 0.91, is currently the smallest of a commonly used plastic. Mainly used for core insulation. The basic method of determination: the surface is relatively smooth, and PE than the hard, burning, the flame on the blue under the blue, dripping, there are shares of smell, after a slight candle flavor.

XLPE / XL-PVC - thermosetting materials, mainly used for insulation, XLPE maximum temperature level up to 150 degrees. Basic identification method: cut a section of wire to remove the conductor, with the fire from the middle began to burn, and then forced to pull off the line, the section is very rounded.

PU - has a very good physical and chemical properties, commonly used in construction machinery and other equipment cable and spring wire jacket. Basic identification method: with magnetic, good elasticity of the expansion of combustion and mixed with dripping.

TPE / PO (thermoplastic elastomer) - low smoke zero halogen flame retardant.

Related articles

-

The face of new energy vehicles in the hot market wiring harness processing usher in new opportunities

China in just two years time beyond the United States, jumped to the world's largest new energy car market, in accordance with national planning, by 2020, new energy vehicles will reach 5 million.The

-

Automotive wiring harness common problems and the impact of what?

With the development of social life and the continuous improvement of living standards, people are not only pursuing material enjoyment but also pursuing spiritual enjoyment. They pay great attention

-

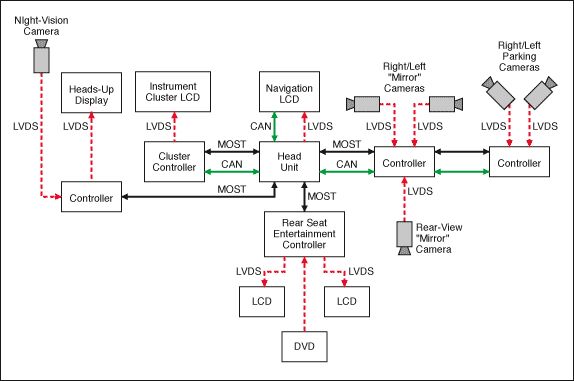

Design of automotive wiring harness

Design of automotive harnessFirst, the schematic design and calculation1. Draw electrical schematics according to the electrical configuration and technical requirements required by the Electrical Des

-

Basic technical requirements for electric vehicle wiring harness (1)

The growing problem of environmental pollution has made the government spare no effort in promoting the development of environmental protection industry, especially the promotion of electric vehicle i

-

Basic technical requirements for electric vehicle wiring harness (2)

At present, we know the various types of electric vehicles in the mileage of how many little let the consumer is not satisfied, so in addition to energy recovery and some other auxiliary technology, t

-

Design Principle of Vehicle Harness

(A) power distribution design Whether the design of the power supply system of the automobile is reasonable is directly related to the normal operation of the automobile electri

-

Intelligent life so that the electronic wiring harness market is more popular

With the country to vigorously promote the new energy vehicles, home appliances "TM" policy and people on the intelligent machine automation replacement speed, highlighting the huge demand for China's electronic wiring harness. In recent years, many joint ventures have emerged, wire harness processing to China to shift positions, China has become an important global harness processing and manufacturing center. From the popularity of household appliances to communications equipment, computers and external equipment, as well as security, solar, aircraft, automotive and military equipment are widely used electronic wiring harness. Industry forecast, especially in China 4G launched, home appliances, cars to the countryside and industrial information and other multi-party

-

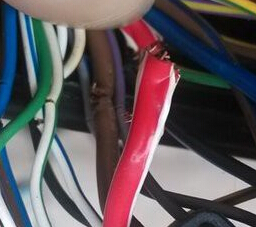

What are the common causes of the wiring harness?

Wire harness as the machine"blood vessels", bear the role of energy and communication transmission, just like people will be sick, the harness will be used for a long time a variety of failures, the f

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite