Terminal harness material selection skills

First, the choice of wire According to the use of different environments, select the appropriate wire, such as: car engine ambient temperature is high, corrosive gases and liquids are also many, therefore, must use high temperature, oil, vibration, Automatic transmission of the wire must be high temperature, resistant to hydraulic oil, the temperature stability is better; weak signal sensors to use shielded wires, such as crankshaft position sensor and knock sensor, ABS wheel speed sensor; door to use bending resistance High wire and so on.

Second, the choice of plastic shell Plastic parts commonly used materials are PA6, PA66, ABS, PBT, pp, etc., design plug-in can be selected according to different needs of different materials, but also according to the actual situation in the plastic to add flame retardant or enhanced Materials to achieve enhanced or flame retardant purposes, such as adding glass fiber reinforced and the like.

Third, the material selection of the terminal material is mainly brass and bronze (brass hardness is slightly lower than the hardness of bronze), which accounted for a larger proportion of brass. In addition, according to different needs to choose a different coating, such as tin, gold and so on.

Fourth, the choice of other accessories Harness accessories play a wear, flame retardant, anti-corrosion, to prevent interference, reduce noise, beautify the appearance of the role, generally based on the working environment and space to select the auxiliary material. Accessories are usually the following:

1, tape - wire harness with PVC tape, acetate tape, insulation tape, conductive tape, copper foil, and so on. Tape in the wiring harness to play bundles, insulation, conductive, marking and so on. Different tape labels can be selected according to different requirements.

2, casing - casing type PVC pipe, glass tube, silicone tube, heat pipe, spiral, etc., play a flame retardant, insulation, protection and other functions. PVC pipe softness and resistance to bending deformation is better.

3, tin - tin in the amount of wire is also relatively large, tin and tin-free tin, silver tin, tin wire, etc., mainly for the end of the wire dip tin and welding. According to the use of different, to choose.

4, metal head class - metal head is mainly used for injection molding, metal head with DC head, BNC head, stereo head, DB head, USB head, DIN head, RCA head. Hardware head also need to choose according to the different use of model specifications and materials and coating.

5, rubber compounds - the same compound for injection molding, commonly used compounds are 45P, 60P, etc., the soft and hard different, according to the need to choose, there are different colors to choose to distinguish.

6, packaging materials - there are some other packaging materials, such as cable ties, the end of the band, PE bags, cartons, aprons, etc., but also in accordance with the packaging requirements to choose. Such as sent to foreign goods on the need to use double-layer carton to packaging.

Related articles

-

The face of new energy vehicles in the hot market wiring harness processing usher in new opportunities

China in just two years time beyond the United States, jumped to the world's largest new energy car market, in accordance with national planning, by 2020, new energy vehicles will reach 5 million.The

-

Automotive wiring harness common problems and the impact of what?

With the development of social life and the continuous improvement of living standards, people are not only pursuing material enjoyment but also pursuing spiritual enjoyment. They pay great attention

-

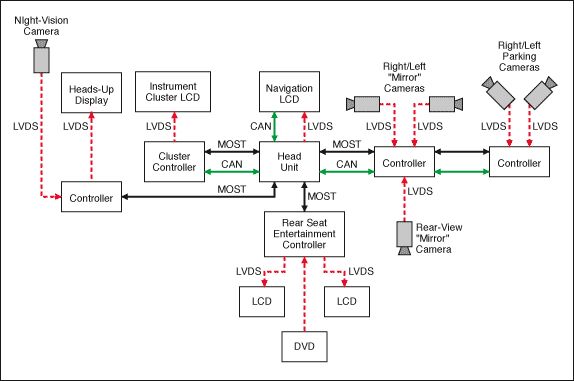

Design of automotive wiring harness

Design of automotive harnessFirst, the schematic design and calculation1. Draw electrical schematics according to the electrical configuration and technical requirements required by the Electrical Des

-

Basic technical requirements for electric vehicle wiring harness (1)

The growing problem of environmental pollution has made the government spare no effort in promoting the development of environmental protection industry, especially the promotion of electric vehicle i

-

Basic technical requirements for electric vehicle wiring harness (2)

At present, we know the various types of electric vehicles in the mileage of how many little let the consumer is not satisfied, so in addition to energy recovery and some other auxiliary technology, t

-

Design Principle of Vehicle Harness

(A) power distribution design Whether the design of the power supply system of the automobile is reasonable is directly related to the normal operation of the automobile electri

-

Intelligent life so that the electronic wiring harness market is more popular

With the country to vigorously promote the new energy vehicles, home appliances "TM" policy and people on the intelligent machine automation replacement speed, highlighting the huge demand for China's electronic wiring harness. In recent years, many joint ventures have emerged, wire harness processing to China to shift positions, China has become an important global harness processing and manufacturing center. From the popularity of household appliances to communications equipment, computers and external equipment, as well as security, solar, aircraft, automotive and military equipment are widely used electronic wiring harness. Industry forecast, especially in China 4G launched, home appliances, cars to the countryside and industrial information and other multi-party

-

What are the common causes of the wiring harness?

Wire harness as the machine"blood vessels", bear the role of energy and communication transmission, just like people will be sick, the harness will be used for a long time a variety of failures, the f

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite