"New energy vehicles breakthrough growth, so that the domestic automotive wiring harness market from low-cost strategic market gradually into a higher price of the technology market." Recently, the industry to assess the current status of the automotive wiring harness industry.

"The development of new energy vehicles does give new opportunities for wireline technology upgrades." During the interview, a number of industry participants gave similar answers.

At the same time, automotive electrification and intelligent also contributed to the harness industry's vigorous development, wire harness technology, processing technology and processing equipment, a new wave of upgrading is accelerating. In addition, the standardization process of high-voltage wire harnesses is also steadily advancing. Recently, by the China Automotive Technology Research Center of Automotive Standardization Institute hosted the national electric vehicle high-voltage wire harness and connector standard seminar held, means that the high-voltage wire harness from the standardization and further step. From the research situation, the automotive wiring harness is moving towards high pressure, lightweight, standardized direction.

■ High-voltage wire harness technology is the key to research

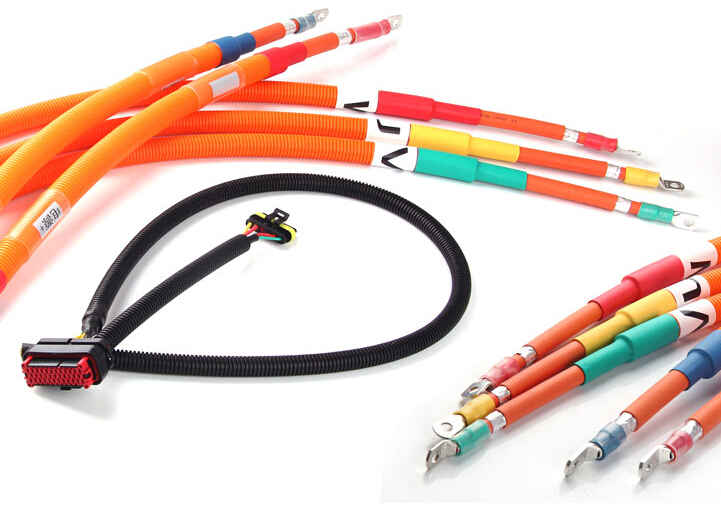

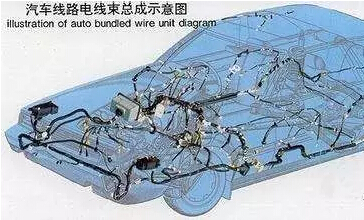

Compared with the traditional fuel vehicles, hybrid electric vehicles, especially pure electric vehicles, in addition to 12V circuit system, there is a voltage more than 300V is mainly used for power drive system circuit system, the system needs to use high-voltage wiring harness to connect the various circuits In the unit. Therefore, high-voltage wire harness is not only a key component of the new energy vehicle high-voltage electrical system, or a safe and reliable operation of new energy vehicles an important guarantee.

"New energy vehicles in the low-voltage wire harness and fuel line wiring harness is not very different, the main difference is that high-voltage wiring harness, high-voltage wiring harness from the wiring harness material, production technology and equipment, etc. have changed significantly." Experts said, high-voltage wire harness in the selection of materials requirements Significantly increased, but also because it involves the safety of electricity, so to increase the power switch or add maintenance on the battery pack maintenance switch, in the maintenance work must be disconnected from high pressure.

The development of high-voltage wire harness technology is also reflected in the wiring harness processing technology. The wiring harness voltage collection and temperature acquisition of the wiring harness on the crushing process requirements are high, high-voltage wire harness in the large diameter part of the terminal material due to restrictions, must use hydraulic equipment, can not use the traditional stamping process. In this regard, the use of new equipment in the processing of waterproof parts must be used in the order quantity is not worth the purchase of equipment, the wiring harness factory generally require the connector supplier has been crimped with a good semi-finished wiring harness for secondary processing, To ensure quality.

■ harness light weight promising

In order to reduce fuel consumption, the number of vehicles on the wiring harness to become the focus of the focus of the enterprise. Industry professionals said that the current use of automotive wiring harness materials mainly copper, so in addition to reducing the cross-sectional area in terms of weight loss, is the use of brighter than aluminum aluminum material. The use of aluminum wire is also one of the future trends, a well-known models on the roof of the wiring harness on the use of aluminum wire, the current domestic wiring harness enterprises are research and development of related technologies. The price of aluminum is about one-third of copper, once the aluminum wire can be applied in the harness, not only can reduce the weight, but also effectively improve the cost.

■ Harness industry standards need to be established

The current new energy automotive wiring harness and connectors have no relevant industry standards and national standards, leading to the quality of related products varies greatly. To connector, for example, large and medium-sized enterprises have their own basic production experience and standards, but there are some workshop-style enterprises to fight the price of the market, the quality is difficult to guarantee.

At present, China is in a large-scale promotion of electric vehicles, the development and implementation of a unified electric vehicle high-voltage wiring harness and connector standards is particularly important. China's earliest research and development of new energy vehicles, a host computer harness development earlier, mastered a number of new energy automotive wiring harness patents, so the current domestic harness companies use this main plant new energy automotive wiring harness standards.

It is understood that the current standards for new energy automotive wiring harness is being developed, some harness companies also use GB / TS29106 standard. The standardization of high-voltage wire harnesses will lay a solid foundation for the entire industry to enter the market scale applications.

In addition, although some of our own enterprises in the development of high-voltage wiring harness and lightweight technology has made progress, but some of the core technology and equipment are still in the hands of foreign brands, such as battery pack maintenance and switching technology and the market is basically the international brand monopoly, The price is high Therefore, in compliance with the standard at the same time, companies also need to pay more attention to the technical upgrade, riding the development of the eastward big step forward.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite