With the development and exploration of human beings in the oceans and the vigorous development of the shipping industry, the demand for carrier ships by sea is also getting higher and higher. Shipping companies hope to improve the seaworthiness of ships and the reliability of equipment operation, Crew requirements and work intensity, to ensure the ship's in-flight. How to maintain the normal operation of the diesel engine (generator set, the same below) during the heavy fuel / diesel conversion under the condition of low load of the generator, low fuel pressure of the incoming fuel and high viscosity of the incoming fuel so as to improve the reliability of the equipment, Reduce equipment maintenance costs and reduce the crew's work intensity.

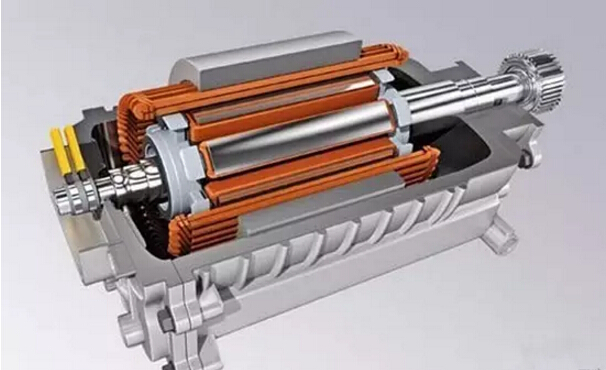

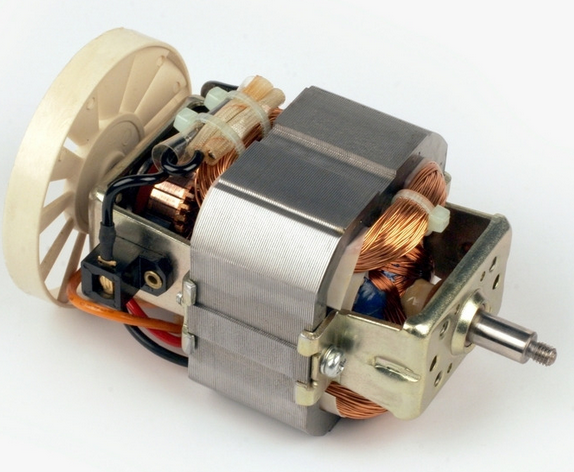

Marine diesel generator

In conventional designs, heavy fuel / diesel conversion of diesel engines is always done manually. Although this conversion method to meet the requirements of unmanned aircraft cabin and related specifications, but there are some shortcomings of manual conversion, easy to make diesel engine failure rate increases, resulting in increased maintenance costs. In view of this, diesel engine maintenance and economic considerations, the diesel heavy fuel / diesel oil supply put forward higher requirements. In manual conversion mode, the system can not switch fuel accurately when the generator is under a low load, the fuel pressure is low and the fuel viscosity is high. In order to meet the requirements, we must optimize the design of heavy oil / diesel fuel conversion. This article will focus on heavy fuel / diesel automatic conversion design.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite