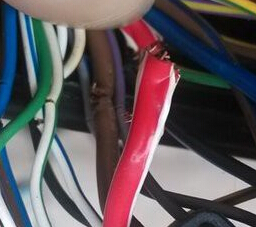

1, coated. With different performance requirements for wire and cable, special equipment is used to coat the outside of the conductor with different materials. Specific can be divided into the following categories:

Around the package: mica tape, non-woven fabrics, ribbons of paper, plastic bags and non-alkali glass fiber tape, in addition to these, there are wire and cotton yarn and other fiber materials.

Longitudinal package: wrinkled aluminum and rubber and other materials.

Extruded: lead, plastic, rubber, aluminum and other materials.

Dip coating: insulating paint, asphalt and so on.

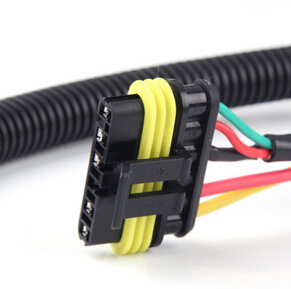

2, stranding. Stranding process generally can be divided into conductor stranding, weaving, winding, into a cable and wire armor and so on. In order to improve the overall integrity of wire and cable and softness, you can make more than two single lines, according to the specified direction intertwined, which is called stranding.

3, drawing. Draw points: single-wire drawing and stranding drawing. In metal pressure machining, a force-machining implementation that forces metal through a die (pinch) at a value of external force, compresses the cross-sectional area of the metal, and obtains the desired cross-sectional shape and size is called metal drawing.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite