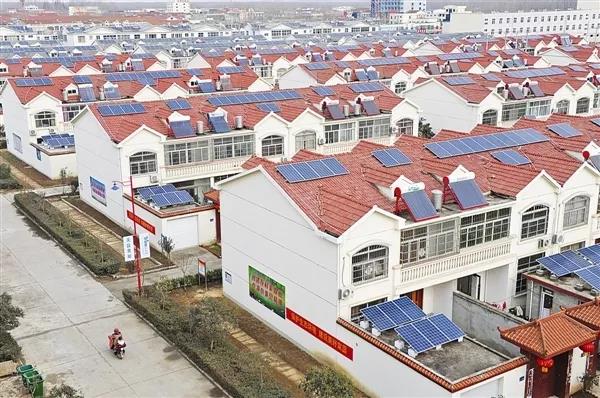

Today, PV power generation has become a hot topic for household investment, retirement care and green living. Power plants built on their own roof more at ease, no need to pay their own home electricity tariffs. Countries, provinces,

municipalities and districts (counties) subsidies according to generating capacity, accurate to every degree of electricity, endless use sold to the national grid, the implementation of standards. Annual income of 10% or more. However, the question is, if the PV plant's quality is not good?

"If the PV board looks colored, is not that a problem with the board?"

Millions of PV people follow the answer

1000kNot ... ... Briefly introduce the three colors of photovoltaic panels deviation: flowers, red and some yin and yang film three.

1

Red piece

Mainly due to the lower amount of corrosion caused by the velvet, if the amount of corroded less than 3, the damaged layer of silicon will be removed is not complete, resulting in the overall color of PE coating will be red.

2

Flower piece

Is due to the high amount of corrosion caused by cashmere, under normal circumstances, the amount of corrosion is higher than 4.5, the silicon is equivalent to a polished, coated after the battery shiny, grain boundaries are more obvious.

3

Yin and Yang films

Can be divided into the following two situations, one immersion situation, and second, there is deviation between the corridor of the amount of corrosion. Immersion problem is produced in the production process, by the level of the front and rear wheel and the front baffle effect, the wafer into the flume, the liquid chemical contact with the wafer there is a difference. So the first contact with the liquid silicon area corrosion is bound to be higher than the contact area after the solution. Corrosion amount of the difference will inevitably lead to inconsistencies in the effect of surface silicon wafer, PE coating will produce a certain color difference. In order to ensure the liquid immersion effect, the need to adjust the flannel wheel and the baffle.

Common color of polycrystalline silicon cells is dark blue, but due to the impact of the production process of PV modules, components will appear color. The appearance of chromatic aberration is a normal condition, and even a qualified PV module has a slight chromatic aberration, which does not affect the service life and power generation of the power station. At the same time, through the adjustment of the production process, the problem of color deviation can be effectively solved.

requires attention① There is a variety of colors on a PV module and the color difference is obvious:

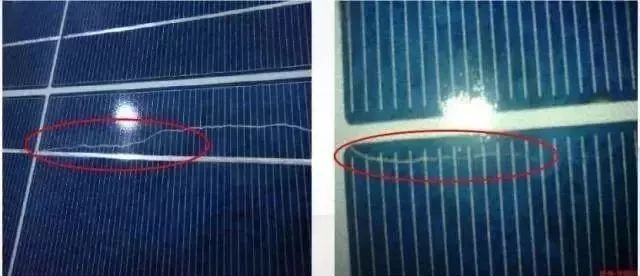

② obvious surface color, broken gate, scratches, wrinkles, cracks, non-erasable objects, defect damage, spot oxidation spots and other phenomena:

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite