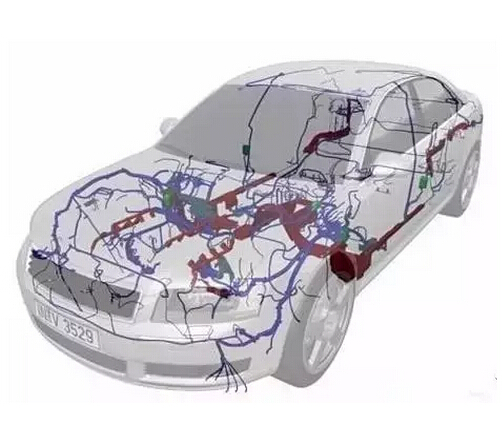

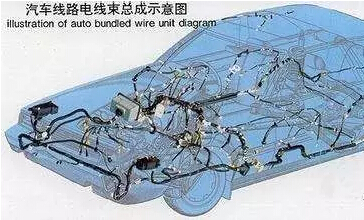

The electronic harness of the automotive wiring harness is highly integrated. The operating conditions and parameters of the vehicle are reflected on the on-board computer through the wiring harness. Whether the quality of the automotive wiring harness is qualified determines whether the vehicle performance is up to standard.

What should be noted in the quality inspection of automotive wiring harnesses during processing? The following wire harness processing plants believe that the following aspects should be analyzed:

1. Does the line meet the requirements?

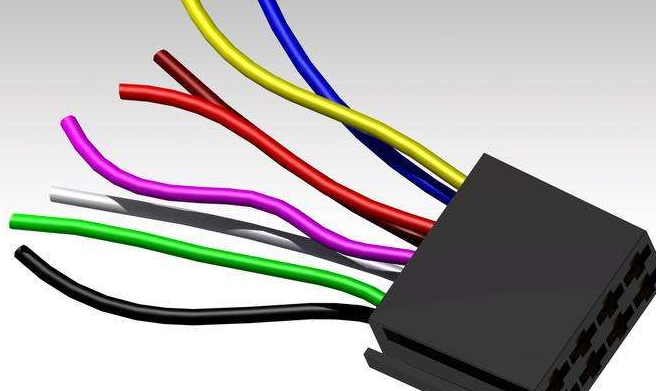

Check the size of the wire is not in line with the relevant requirements, the model is not correct. The incision must be neat, the wire cannot be scratched, and the wire cannot be dirty.2. Is the marshalling process neat?

Check that the trim is not neat, the size is right, and the core cannot be drawn when trimming.

3, Is peeling skin neat?

Check whether the peeling opening is neat, the size of the peeling is not correct, and it is not possible to strip the grouping wire and the core wire and remove the copper wire; the insulator must not be peeled off during the half peeling.

4. Is the shrink tube size right?

Carefully check the type and size of the shrink tube is not correct.

5, is the appropriate solder temperature suitable?

Check the temperature of the soldering tin is not correct; before preparing the solder, the core wire and the copper wire should be finished and checked for bent, forked, and folded.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite