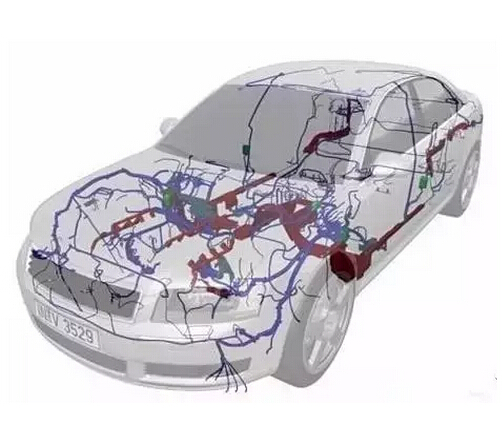

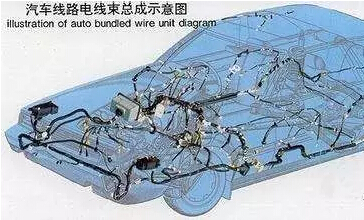

Due to the large number of automotive wiring harnesses, in the process of integrated cabling of the system, operations such as splitting, wire bonding, banding, and fixing are performed according to the wiring process requirements. After the integrated wiring is completed, the connectors are relatively fixed, and the margin of space activity of the wire harness is small, and only by manual It is difficult to conduct the inspection. First of all, too many human participants have a certain influence on the reliability of the whole machine. Secondly, a large number of testing tasks cannot guarantee the product development cycle. Therefore, it is imperative to introduce special automatic detection equipment for testing.

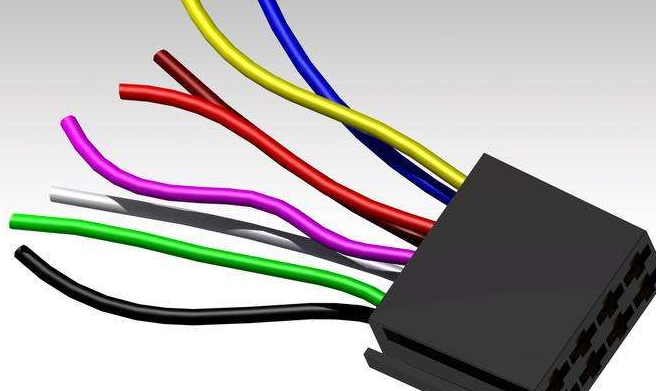

After the system design is completed, first connect the control circuit of the solenoid valve, limit switch, and 24V power supply. When the limit switch is closed, the solenoid valve must have the action; then connect the electrical harness lines and pneumatic lines, the electrical lines mainly include pneumatic Fixture module I/O interface, limit switch circuit, solenoid valve circuit, indicator circuit, buzzer circuit, upper computer communication circuit, etc. Pneumatic pipeline mainly includes cylinder inlet and outlet port pipeline, solenoid valve inlet and outlet port pipeline, and gas Source total piping.

The system can be configured to automatically download configuration files to the controller at power up. This allows you to update the configuration file just by performing normal software operations without requiring any hardware actions and specialized software.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite