Most of the burned parts are connected to the plug where they are connected, causing heat to burn out the connector's plastic plugs. Generally, the burned wires are the headlamp harnesses, the cigarette lighter harnesses and other overloaded wires, and it takes time and effort to replace the entire vehicle harness. Fei Gong, the following describes the car wire harness plug processing and maintenance program:

1. Find a piece of paper or use a camera recorder to record the position of the wire harness. Use a thin steel pin to gently pry the wire harness terminal off. Allow all the harness terminals to be separated from the burned plug. It is the first step;

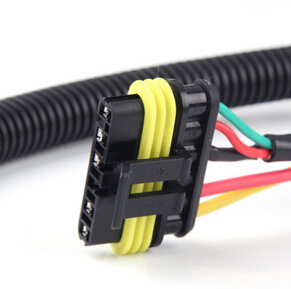

2. In the automotive wiring harness processing manufacturers to buy a good connector (that is, harness connector) and terminals, wire harness dedicated crimping pliers, as well as heat shrink sleeve;

3. Remove the damaged part of the burned wire harness. Put the heat-shrink sleeve over and fit it properly. Connect the wire harness to the terminal block and use a crimping pliers to fix the wire into the connector. Heat it in hot water. With a heat-shrink sleeve, the copper wire can be tightly wrapped, and the maintenance method is the same as the new one.

Summary: Using this method to process wire harnesses can eliminate the need to replace the entire vehicle wiring harness, eliminating the cost of purchasing automotive wiring harnesses, and is simple and practical. The maintenance automobile harness connector, wire harness terminal block, and crimping pliers can be used to manufacture automotive wire harnesses. Direct purchase.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite