When we focus on energy and energy storage applications, we will find that capacitors are "unknown heroes" in the field. As a passive device, the capacitor has two terminals that store energy and release energy when needed—often used as a “standby” power supply. In daily life, the use of capacitors is wider than we think. For example, capacitors can be used with simple everyday items such as alarm clocks. We can also have a charging capacitor for emergency use in case of power failure. Or take the alarm clock as an example. If the power is off, the capacitor will discharge - deliver current to the clock circuit to ensure it continues to run. With the increasing use of capacitors, new capacitors are entering the market, and supercapacitors (also known as electric double layer capacitors, EDLC) are now being used on a larger scale. New energy vehicles, such as pure electric vehicles, hybrid vehicles and electric buses, rely on supercapacitors because they have much larger charge storage space than standard capacitors, and some high-power and renewable energy applications are also using supercapacitors. technology. Other applications include defense, energy, aerospace and various industrial applications.

Use of capacitors and supercapacitors

The automotive sector is a key market for capacitors and supercapacitors, and many of the functions of automobiles provide a place for capacitors. Capacitors are required for start/stop functions and power steering, and hybrid vehicles require supercapacitors with greater power capacity. As electric vehicles continue to evolve and enter the mainstream automotive market, the demand for capacitors will increase further. Future technological advances have the potential to make supercapacitors replace lithium-ion batteries as a source of power and provide mileage comparable to gasoline and even diesel-powered vehicles.

The railway industry has also begun to fully exploit the application potential of supercapacitor technology. For example, the Urbos 3 tram, manufactured by CAF, a railway company in Zaragoza, Spain, uses a series of supercapacitors located in the upper part of the cabin to recover braking energy – saving 35% of electricity. Supercapacitors can be recharged at tram stops without the need for overhead cables or between some docks without the need for cable connections.

In the field of renewable energy, supercapacitors play an important role in applications such as wind turbines. The blades of the turbine must be adjusted periodically to ensure that the turbine operates at optimum levels that meet wind conditions and avoid mechanical stress (stress). To do this, adjust the pitch control system if necessary. In the event of a power failure, the supercapacitor can be turned on and deliver enough energy to return the blade pitch to a safe position and shut down the turbine, which is not necessarily achievable.

Supercapacitors play a key role in the future development of photovoltaic (solar) and wave power applications. Photovoltaic and wave power technologies are volatile in terms of output power. Supercapacitors alleviate this effect: Supercapacitors help provide a more constant power level through a process called "homogenization." Both solar and wave energy applications generate an alternating current (AC) voltage that must be converted to a direct current (DC) voltage by a bridge rectifier. However, if the power supply is used without using a capacitor, the output voltage of the power supply will fluctuate when the voltage oscillates between 0 V and the maximum voltage. For example, if the power is used for a light bulb, the light bulb will be flickering. Capacitors ensure that the smooth output of the power supply is not interrupted by constantly storing energy as the output voltage increases and constantly releasing energy as the output voltage decreases. The implementation of this process extends the life of expensive, dedicated components in these applications, ultimately making them a more reliable clean energy source.

The challenge of aluminum electrolytic capacitors

Aluminum electrolytic capacitors and supercapacitors have a weakness: electrolyte dryness is prone to occur during the service life – which is usually caused by imperfect seals in the capacitor terminals. A small amount of moisture can penetrate the sealing material, causing gas to accumulate inside the capacitor. Electrolyte drying causes continuous deterioration of performance, and to offset this effect, it is necessary to use a larger size or use two capacitors. Slow and continuous evaporation of the electrolyte can result in a capacity loss of up to 20% with a large loss of efficiency.

Polymer seals commonly used to seal capacitor terminals are a weak link in capacitor construction and have the disadvantage of causing damaging moisture infiltration and evaporation loss of electrolyte. Like all organic materials, polymers tend to age and become brittle over time, and then lose their air tightness. As moisture penetrates through the defect seal, the electrolyte then evaporates, ultimately resulting in significant loss in capacity and life.

Improve air tightness and help increase capacitor capacity and life

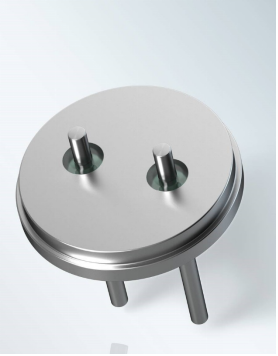

A remedy for electrolyte leakage is to use a capacitor cap. The capacitor terminal can be sealed into the aluminum cover by a special glass seal instead of a seal made of an organic compound. This prevents moisture from entering the capacitor through the electrode terminals and eliminates the problem of electrolyte dryness. Since glass is an inorganic material, glass seals remain permanently sealed because they do not age or wear over time. Glass seal covers are customizable to meet a wide range of applications for small and large canister capacitors - including radial, axial, snap-on, supercapacitor and electric double layer capacitors. Glass-Aluminum Seal (GTAS®) is a new technology developed by glass specialist SCHOTT for high energy density capacitors and batteries. The design is based on the company's expertise in special glass and glass-to-metal seals developed in 1939.

Glass-aluminum seals (GTAS®) have a wide range of external advantages. Glass-aluminum seals are available over a wide temperature range and are resistant to temperatures from -40 °C to +150 °C. Increasing the seal also means that capacitor units of the same size or smaller can have higher capacitance. The reliable sealing of non-aged glass seals not only extends the shelf life of the product, but also extends the life of the product, even in harsh environments.

Excellent glass-aluminum sealing performance and wide application

Aluminum electrolytic capacitors, including cutting-edge supercapacitors, are increasingly being used in emerging applications. Potential applications include new energy vehicles, high power applications, heavy industries and renewable energy. These applications impose new technical requirements on capacitors that require long-term performance. This innovation requirement is where GTAS takes advantage: leak-proof capacitor caps can be used in capacitors of different sizes to meet their design requirements.

The GTAS capacitor cover reduces capacitor package size by 20%, reduces capacitance loss by 60% and internal resistance by 50%. The GTAS Capsules can be used at extreme temperatures and extend product life by 10-15 years compared to organic seals.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite