For the inspection of automobile wire harness elongation, it should be inspected according to the elongation and relevant national standards. If customers have special requirements, they must be strictly controlled according to their requirements. The specific steps are to turn on the elongation tester, and then carefully observe whether the sensor on the left is in the original position, and whether the reading displayed on the instrument is zero. If the sensor on the left is not in the original position, If the reading displayed on the instrument does not return to zero, then you must immediately press the recovery key and the zero key. Then gently open the induction clip, place a section of the copper wire to be inspected in the induction clip, then press down the induction clip, then straighten the copper wire and place the other end in the other induction clip. Lower the induction clamp, clamp the copper wire firmly, and press the test button. Finally, after the copper wire is pulled and stopped by the induction clip, observe the reading displayed on the instrument, and the above reading is the elongation of the copper wire to be detected.

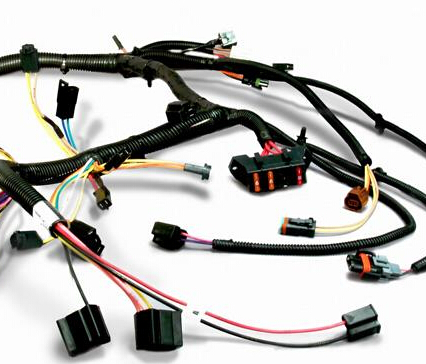

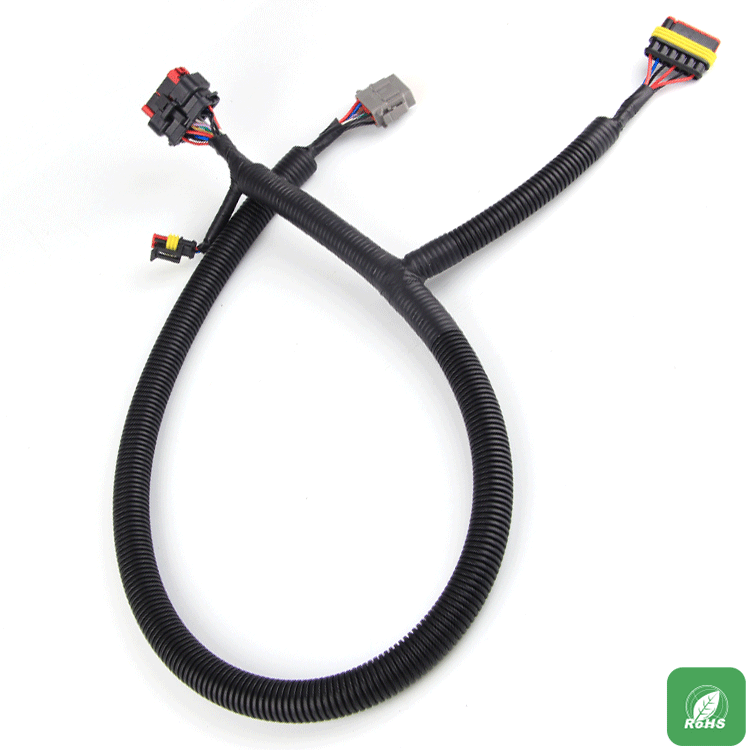

1. Detailed specifications and processing can be customized according to customer requirements.

2. Components, such as terminals and housings, are JST, AMP and Molex world brand materials, which can also be specified by you.

3. All products are RoHS compliant, ensuring that the quality before shipment is 100% excellent.

4. The company professionally accepts multiple varieties and small orders.

5. Professional design drawings, quotations, please contact our professionals.

Packaging: inner packaging, cable tie or PE film

Outer packaging: Long size packaged in transparent plastic bags

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite