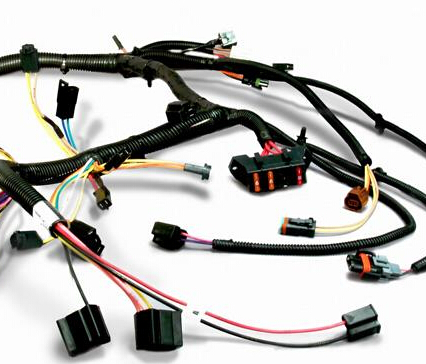

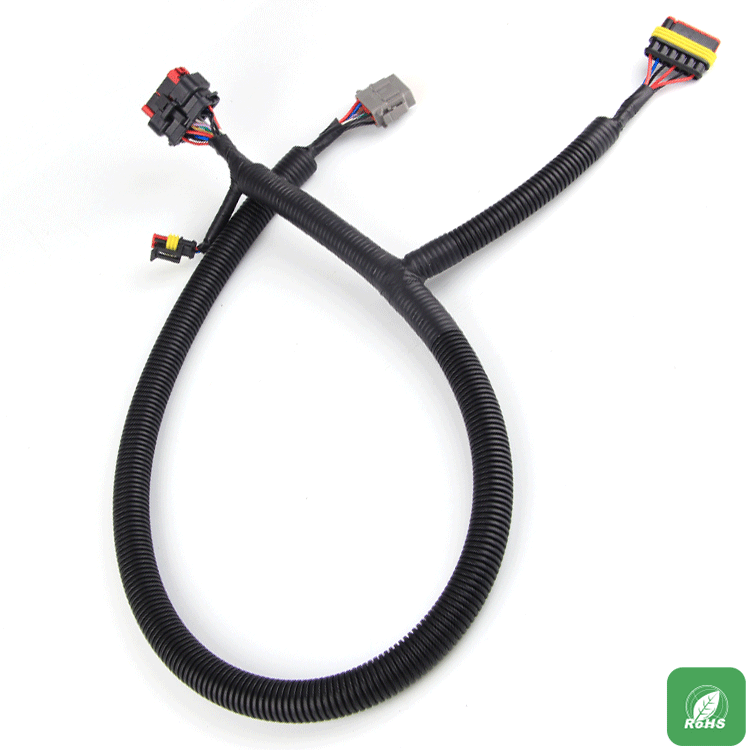

In order to ensure the quality of the wiring harness during wiring harness, the following links are required in the quality inspection of the harness:

1. Marshalling: Check whether the trim is neat and the size is correct. When trimming and marshalling, you cannot draw the core line.

2. Cutting wire: check whether the size of the wire meets the relevant requirements and the model is incorrect. The cuts must be neat, the wires must not be scratched, and the wires must not be dirty.

3. Skinning: Check whether the skinning mouth is neat, and the skinning size is correct, and the braided wire and core wire cannot be damaged.

4. Stripping the inner skin: Check whether the stripping mouth is neat, the size of the stripping is correct, whether the core wire is peeled, and whether the copper wire is stripped; the insulator must not fall off when it is partially peeled.

5. Set of shrink tube: Carefully check whether the model and size of the shrink tube are correct.

6. Preparing solder: Check the temperature of the tin furnace is correct; arrange the core wire and copper wire before preparing the solder, and check whether it is bent, split and discounted.

7. Soldering: Check that the temperature of the electric soldering iron is incorrect; do not burn the insulation skin, the tin spots should be smooth, no tin tips, and false soldering and false soldering.

8. Terminal crimping: Check whether the specifications of the terminal and the wire are correct; whether the terminal crimping is inclined, and there is no lama mouth.

9. Terminal insertion: Check whether the models of the terminals and connectors are correct; whether the terminals are deformed or damaged; check whether the terminals are inserted incorrectly, are missing, or are not inserted properly.

10. Assemble the shell: check whether the shell is scratched, incorrectly installed, or burr, whether there are missing components, and whether the screws are oxidized, loosened, twisted, and discolored. If the housing is directional, then it must be assembled as required.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite