China Financial Enterprise Trust International Consulting announced the "In-depth investigation and analysis of China's fastener industry and investment risk prediction assessment report for 2021-2027"

(1) Industry definition and classification: Fasteners are the general term for a type of mechanical parts used when two or more parts (or components) are fastened and connected into a whole, mainly including: bolts, studs, Twelve categories of screws, nuts, self-tapping screws, wood screws, retaining rings, washers, pins, rivets, assemblies and connection pairs, welding nails, etc., are a class of mechanical parts that are used for fastening and connection and are extremely widely used.

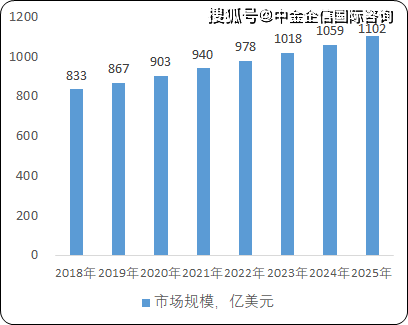

(2) Overview of the global fastener industry: The demand for fasteners is mainly driven by commodity price fluctuations, including the prices of coal, copper and iron ore, product life cycles, competitive pressures and other economic factors affecting the construction and equipment industries . The global industrial fastener market size is estimated at 83.34 billion U.S. dollars in 2018. Thanks to the great improvement in living standards, which stimulates the demand for durable goods, the global industrial fastener market is expected to witness rapid growth. In the forecast period from 2019 to 2025, it is expected to grow at a compound annual growth rate of 4.1%. By 2025, the global industrial fastener market will reach US$110.24 billion. The fastener manufacturing trend is developing towards the production of innovative products (such as special, micro and hybrid fasteners) to adapt to changing consumer needs, which heralds the continuous growth of the market in the future.

2018-2025 global industrial fastener market size analysis

Statistics: CICC Enterprise Trust International Consulting

Looking at the proportion of global industrial fastener applications in 2018, the automotive industry is currently the main application market for the fastener industry, followed by industrial machinery and aerospace. In addition, the demand for industrial machinery such as construction and mining is expected to grow at a compound annual growth rate of 4.4% during the forecast period. The demand for lawn and gardening equipment is expected to grow at a compound annual growth rate of 3.2%. The demand for downstream applications is constantly increasing. The upward trend contributes to the stable development of the fastener industry.

(3) Overview of my country's fastener industry: After more than 40 years of reform and opening up, my country's fastener industry has completed the transformation from small to large, and its output ranks first in the world. It is a veritable large producer and exporter. As the most basic and most versatile mechanical basic parts, the fastener industry plays a pivotal role in the country's new strategic emerging industries, with broad market demand and good development prospects. Most of the fastener companies have low automation, backward technical equipment, poor product quality, low quality, and small business scale. Some high-end fasteners in my country (mainly key fasteners for high-speed locomotives, aviation, aerospace, and aircraft manufacturing) still need to be imported. The main reasons for not being self-sufficient are poor material stability, manufacturing technology level, and management technology that require zero defects from products. There is still a big gap. The domestic fastener production capacity of low-end products is seriously surplus, and the supply of high-end products is insufficient. The adjustment of the industrial structure is imminent. Now that my country’s economic development has entered a new normal, the growth rate of fasteners will inevitably shift from high-speed to medium-speed; the development mode will shift from extensive scale and speed to intensive growth in quality and efficiency; structural adjustment will shift from incremental capacity expansion to the coexistence of inventory and increment. In-depth adjustments; the development momentum has shifted from traditional growth points to innovative growth points. The new normal will bring new development opportunities to Chinese fasteners.

my country's fastener industry has maintained rapid development in recent years, and the output, sales volume, and the degree of nationalization have continued to increase. Fasteners are widely used in various machinery, equipment, vehicles, ships, railways, bridges, buildings, structures, tools and instrumentation and other fields, and are closely related to the development of the equipment manufacturing industry. With the steady development of my country's economy, the continuous increase in the demand for fasteners in the downstream industry, and the strong support of national policies, the size of the fastener market will continue to rise.

China Financial Enterprise Credit Statistics: From 2012 to 2019, the main business income of China's fastener manufacturing industry continued to rise until it reached its peak in 2017 and then declined. By the end of 2019, the main business income of China's fastener manufacturing industry was 122.059 billion yuan. The specific situation is shown in the following figure:

2012-2019 China's fastener manufacturing industry's main business revenue analysis

Statistics: CICC Enterprise Trust International Consulting

In 2019, the fastener industry encountered various challenges and difficulties. The impact of the Sino-U.S. trade war was apparent, and exports declined significantly; international trade frictions increased, and corporate exports were blocked; raw material prices remained high and production costs increased; environmental monitoring With greater efforts, many companies are required to rectify, relocate, or even shut down; factors such as high overall costs in all aspects restrict the companies from further expanding production and exports. In 2019, China imported 267,000 tons of steel standard fasteners, a year-on-year decrease of 15.87%, and the import value was US$2.839 billion, a year-on-year decrease of 11.84%.

(4) The development trend of the fastener industry: Compared with the advanced level of foreign countries, the technical level of the fastener industry in my country is still far behind, which is mainly reflected in the production equipment and raw materials. Most of the fastener manufacturers in my country are small in scale, backward in production technology, poor in equipment, slow in technological innovation, and poor in surface treatment. This has led to an excess of production capacity for low-level products in the fastener industry in my country, while high-end fastener products are in short supply; in addition; , The variety, specification and quality of domestic fastener steel cannot fully meet the requirements of the fastener industry, resulting in the transfer of processes that should have been solved in the metallurgical industry to fastener companies. At present, only a few companies can rely on their own Strong comprehensive strength solves this problem.

At present, my country's national economic construction is entering a new stage of development, and advanced manufacturing represented by large airplanes, large power generation equipment, automobiles, high-speed trains, large ships, and large complete sets of equipment will also enter an important development direction. As a result, the use of high-strength and high-performance fasteners will continue to grow, which prompts fastener companies to continuously improve product quality and performance, accelerate technological upgrading, enhance independent innovation capabilities, and continuously optimize product structure and broaden products. Categories to improve the intelligence level of procurement, production, sales and management.

Innovative fastener technology is the support for the development of fasteners, and the trend of technological development determines the direction of industrial development to a considerable extent. The core technology of fasteners is not only to accelerate the research and development of special steel grades, but also to integrate technical details and know-how in the manufacturing, testing and heat treatment of fasteners. In the future, my country’s fastener technology will gradually move closer to foreign advanced levels in terms of material selection, structural design, manufacturing technology, special technology, testing technology, surface coating technology, and quality control. At the same time, the production and manufacturing will be intelligent, integrated and supernormal. Development will also be the main trend of industry technology development.

①Intelligent: Intelligent manufacturing is a new manufacturing mode of fasteners, and it is the inevitable result of the development of automation, digitization, networking and intelligence in mechanical manufacturing. As labor costs continue to rise, product quality requirements continue to increase, and demand diversity is becoming increasingly prominent, the fastener industry has an increasingly urgent need for intelligent manufacturing. Intelligent manufacturing will greatly improve the production efficiency and benefits of fasteners, reduce the labor costs of enterprises, improve the working environment and labor intensity of workers, and improve product quality and reliability. Intelligent manufacturing includes the intelligence of the manufacturing process and the intelligence of the equipment. The intelligentization of the manufacturing process requires the development of various intelligent manufacturing systems, automated or intelligent production lines, and then the construction of digital workshops, digital factories and digital enterprises. The intelligentization of equipment requires enterprises to increase investment in scientific and technological research and development and technological innovation, and improve the production capacity of production equipment and the degree of production matching. The key technical problems to be overcome in the next few years for the intelligent manufacturing of fasteners are: automatic and intelligent cold forging precision forming technology, cold forging machine technology and equipment for large-size fasteners, precision forming technology for complex shape fasteners, automated logistics equipment and Automatic heat treatment production line, etc.

② Fusion is the cross fusion of multiple disciplines, and the combination of multiple processes is the trend of the new era. The integration of mechanical manufacturing technology and information technology and various high and new technologies, the integration of machinery and materials, and the integration of technology and culture will continue to inject new vitality into the development of fasteners. The application of fusion technology will produce new fastening components, manufacturing processes, processing equipment and systems, greatly enriching the product system of fasteners and expanding product functions.

In addition, what is particularly worth mentioning in fusion manufacturing is process compounding and integrated innovation. Process compounding means that the original multiple processes and multiple processes are combined and integrated into one device, which greatly reduces process links and site occupation, improves work efficiency, and improves product quality. Integrated innovation is an innovative activity that transforms various fusions into scientific and technological achievements and productivity. It is an important way of integrated manufacturing and the main type of current fastener technology innovation.

③Supernormalization: With the expansion of people's living space and the rapid development of technology, the requirements for fasteners are getting higher and higher. They are used under conditions such as extremely large, extremely small, ultra-high temperature, ultra-low temperature, ultra-high speed, and ultra-low speed. The demand for fasteners is increasing, and the process technology for manufacturing these fasteners is very different from ordinary fasteners. Supernormal manufacturing includes two meanings: one is the manufacture of fastener products used under abnormal conditions; the other is the process and technology of producing these fastener products. In the future, ultra-precision manufacturing, ultra-high-performance product manufacturing and ultra-normal forming processes will be a symbol of the level of fastener manufacturing, and will also become the key research and development direction of high-end fastener manufacturers.

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite