Power battery is the core of the new energy battery, the role of the battery separator is also important, mainly in a small space between the positive and negative plates of the battery to separate the two poles to prevent short circuit, but to ensure that the electrolyte ions are positive Between the negative free passage. Therefore, the diaphragm has become the core material to ensure the safety and stability of lithium-ion batteries.

Electrolyte is to isolate the source of combustion, the diaphragm is to improve the heat resistance temperature, and heat dissipation is sufficient to reduce the battery temperature, to avoid excessive heat caused by the battery thermal runaway. If the battery temperature rises sharply to 300 ℃, even if the diaphragm does not melt and shrink, the electrolyte itself, the electrolyte and positive and negative will also have a strong chemical reaction, the release of gas, the formation of internal high pressure and explosion, so the use of suitable cooling method to Important.

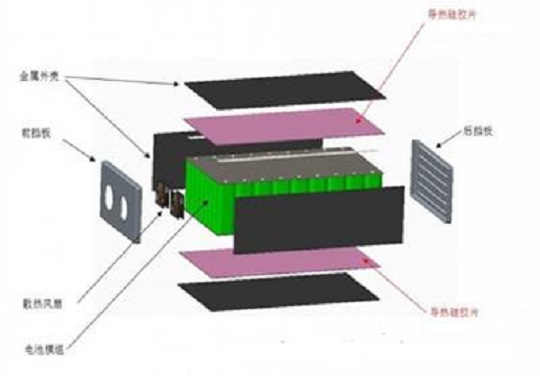

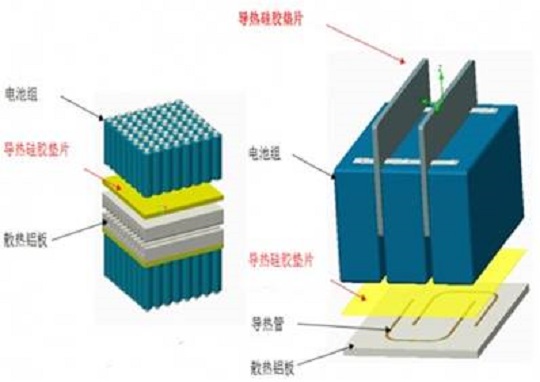

Power battery pack cooling structure cooling method introduced

Power battery pack cooling structure cooling method

1, One end of the battery pack to install cooling fan, leaving the other end of the vent, so that the air flow in the gap between the batteries to accelerate, away from the work of batteries produced high heat;

2, at the top and bottom of the electrode plus thermal silica pad, so that the top, the bottom of the heat is not easily distributed through the TIF thermal conductivity of silicon conduction to the metal shell on the heat, at the same time the silicon sheet of high electrical insulation and anti-piercing performance of the battery Group has a good protective effect.

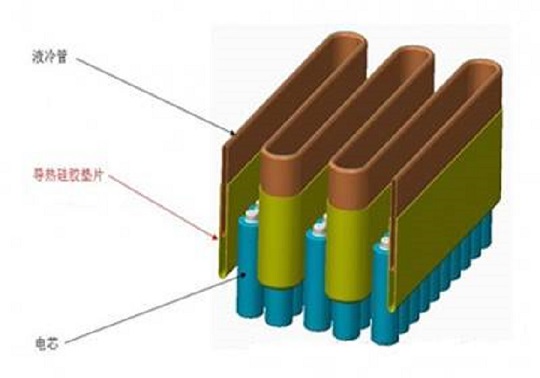

Power battery pack cooling liquid cooling method introduced

2, the thermal conductivity of silicon film, good insulation properties and high resilience, can effectively avoid the friction between the cell damage problems, and short-circuit between the hidden dangers batteries, water-cooled program is the

best supporting material.

Power battery pack natural convection cooling method introduced

1, Such a battery pack space, good contact with air, the exposed part of the natural heat exchange through the air, the bottom part of the natural heat transfer through the radiator heat, thermal silica film to fill the gap between the radiator and the battery pack, thermal conductivity, shock absorption ,insulation.

2, the heating film program used in new energy vehicles more than the market before the start of the battery preheat the heat of the heat transfer through the thermal silica film to the battery pack, preheat the battery, thermal silica film has good thermal conductivity, insulation properties, Abrasion resistance, can effectively heat and protect the battery pack and the heat generated between the friction wear, short circuit and so on. The company is located

RCCN WeChat QrCode

RCCN WeChat QrCode Mobile WebSite

Mobile WebSite